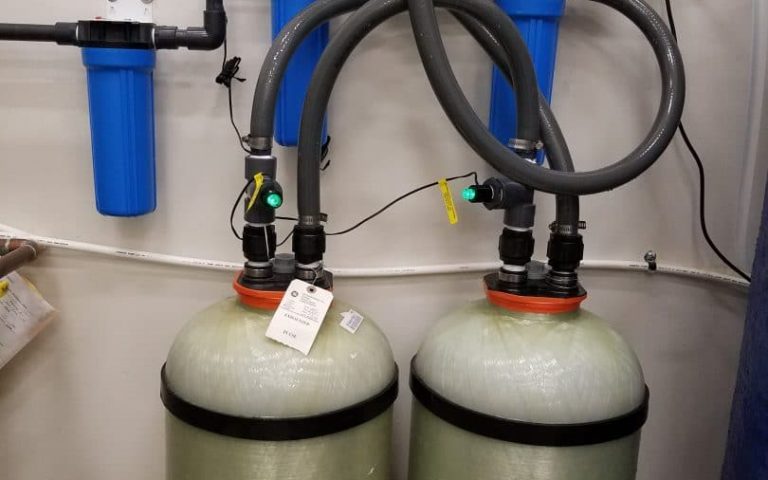

Resin Replacement For DI System & Softener

Professional Resin Replacement For DI System & Softener Complete Water Solutions recently performed a resin replacement service for both a DI Water System & Softener System. Over 400 Cubic Feet Were Replaced. The work performed included Lock Out & Tag Out Of Water System Confined Space Safety Review Air Monitoring Removal [...]