Deionized Water Service

What Is Deionized Water?

Deionized water gives you the ultra-pure, mineral-free water you need for your lab, food processing, and pharmaceutical manufacturing. Deionization (DI) water treatment systems produce ultra-pure water by removing total dissolved solids (TDS) and ionized minerals from source water.

This process removes the most common ionized minerals found in source water. They include calcium, magnesium, sodium, nitrate, potassium, chloride, iron and sulfate. While they may not be problematic in general use, in specialized industrial applications requiring pure water even the slightest variation can cause issues.

Deionized Water tank service (also known as service DI) is just one part of a high-purity water system. Complete Water has decades of experience with all aspects of high-purity water systems, from the pre-treatment system to the storage, disinfection, and distribution of deionized water. Additional services we offer include system sanitization, UV disinfection and TOC removal, quality instrumentation and calibration, chemical injection systems, high-purity piping installation, pre-filters, point-of-use filters, storage tanks, system automation, laboratory analysis services, PLC system installation and support, remote monitoring, scheduled maintenance service, spare parts, and operator training and documentation.

Who Benefits From Deionized Water?

Medical Offices

Laboratories

Pharmaceutical companies

Cosmetic companies

Electronics manufacturing plants

Food processing plants

Electroplating and anodizing

DI Processes For Your Applications

DI Exchange Tanks

Deionized water tanks remove ionic contaminants that can harm industrial and commercial processes. We offer a variety of tank sizes and types to meet different flow and quality requirements.

Our deionized water tanks require no chemical handling, water discharge, or maintenance. Once a tank reaches exhaustion, we will send a technician to remove it and replace it with a freshly regenerated tank.

The Process Explained

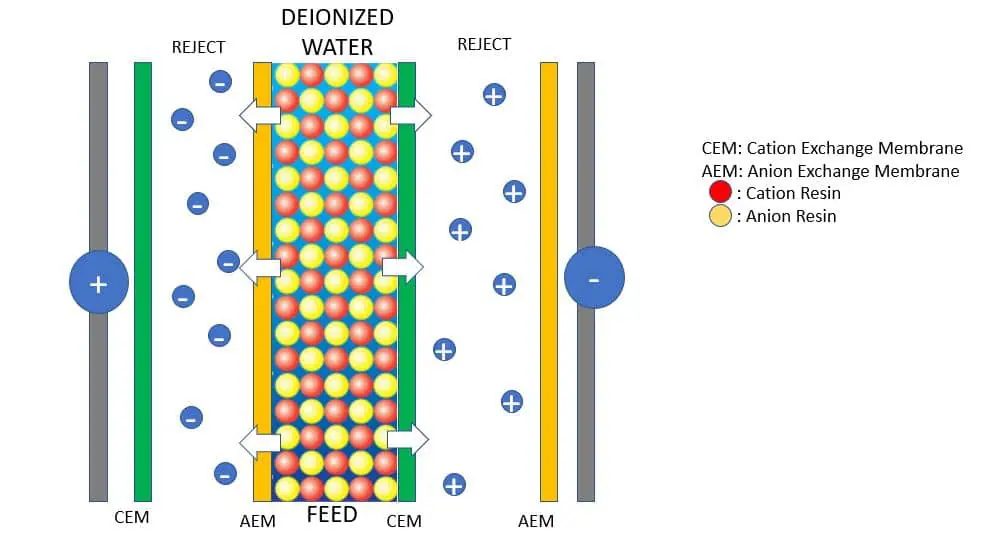

Deionization (DI) exchange is a process that uses ion exchange resins to remove ionic contaminants from water. Ion exchange resins are small beads made of synthetic material that have electrically charged functional groups attached to them. These functional groups can attract and hold oppositely charged ions in the water.

When water passes through a DI exchange system, the ionic contaminants are attracted to the functional groups on the ion exchange resins and are exchanged for more desirable ions, such as hydrogen and hydroxyl ions. This process continues until all of the ionic contaminants have been removed from the water, resulting in high-purity deionized water.

There are two main types of DI exchange resins: cation resins and anion resins. Cation resins exchange positively charged ions, such as sodium, calcium, and magnesium, for hydrogen ions. Anion resins exchange negatively charged ions, such as chloride, sulfate, and nitrate, for hydroxyl ions.

DI exchange systems can be configured in a variety of ways, depending on the specific application. Some systems use single-bed resin tanks, while others use multi-bed resin tanks. Multi-bed resin tanks contain multiple types of ion exchange resins in a series, which allows for more efficient removal of a wider range of ionic contaminants.

Electronic Deionization (EDI)

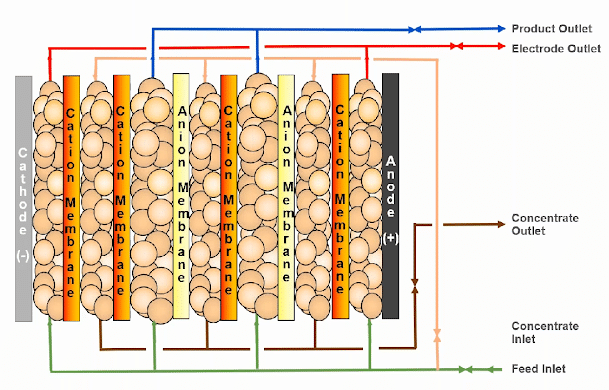

Electronic deionization is high-purity water treatment equipment that is used to produced Deionized Water using a process that combines ion exchange and electrical current. EDI systems are typically used to polish reverse osmosis (RO) permeate to produce ultrapure water for critical applications, such as semiconductor manufacturing, pharmaceutical manufacturing, and power generation.

The Process Explained

EDI systems use ion exchange resins to remove ionic contaminants from water. The resins are continuously regenerated using an electrical current, which eliminates the need for chemical regeneration. This makes EDI systems a more environmentally friendly and sustainable option than traditional ion exchange systems.

EDI systems typically consist of three main components:

- A pre-treatment system: This system removes any particulate matter or other contaminants from the water that could damage the EDI resins. Best practice and most common is Reverse Osmosis Water.

- An EDI stack: This is the core of the EDI system and contains the ion exchange resins and electrodes.

- A post-treatment system: This system removes any remaining contaminants from the water and ensures that it meets the required purity specifications.

We’re Here For You!

You can browse our online catalog to find the industry’s best deionized water systems for sale. If you have any questions, fill out our online contact form or give us a call at 855-787-4200 to speak with a representative.

Complete Water Solutions DI Services

Resin Replacements

Once a tank reaches exhaustion, we will send a technician to remove it and replace it with a freshly regenerated tank. We carry high quality DuPont replacement resins for several of the most popular systems. Our qualified service technicians are here to advise you, so you get the right product for your system.

Top-Industry Brands

We offer electrodeionization units from brands like Veolia Water Technologies & Solutions and SnowPure. We’ll help determine the right system for you, install it, teach you how to use it and keep it running at peak performance.

Professional Experience

Our team is well-trained and knowledgeable with over 40 years of combined experience. When you need industrial water treatment services, we will work with you every step of the way to ensure you get the support you need — whether it’s for a repair, the replacement of a specific part, or the installation of a new system.

We Offer Everything You Need For Your DI Filter System

Additional services we offer include system sanitization, UV disinfection and TOC removal, quality instrumentation and calibration, chemical injection systems, high-purity piping installation, pre-filters, point-of-use filters, storage tanks, system automation, laboratory analysis services, PLC system installation and support, remote monitoring, scheduled maintenance service, spare parts, and operator training and documentation.

Deionized Water tank service (also known as service DI) is just one part of a high-purity water system. We have decades of experience with all aspects of high-purity water systems, from the pre-treatment system to the storage, disinfection, and distribution of deionized water.