Reverse Osmosis (RO) Membrane Cleaning Services

Complete Water Solutions Does Not Service Residential Projects at This Time.

On and Off Site RO Membrane Cleaning Services

Consistently and efficiently performing RO membrane cleaning services on your RO system is one of the simplest ways to maintain efficiency of your RO System.

Virtually all the major membrane manufacturers agree on the following statements:

- Reverse Osmosis membranes should be cleaned when normalized flow decreases by 10% from the initial acceptance test conditions.

- Reverse Osmosis membranes should be cleaned when the overall pressure drop increases by 15% over the initial acceptance test conditions.

These two simple, explicit statements often go ignored, even though it has been demonstrated that the optimum cleaning response is achieved when these guidelines are followed. It can be difficult to recover performance if the system operates in a fouled condition for an extended period of time. Operating in a fouled condition can also cause irreversible damage to the membrane performance, which would require costly replacements if left unchecked.

Protect your investment by having your RO membrane cleaned periodically. Cleaning can prevent damage to your system while extending the life of your membranes, thus saving you money on replacements. Complete Water Solutions offers expert solutions for your RO system, including RO membrane cleaning.

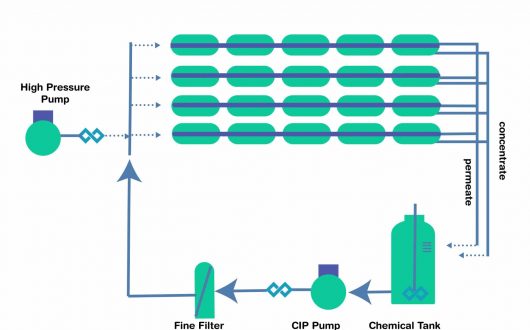

Reverse Osmosis Membrane Cleaning Procedure

Cleaning your RO membrane can be a simple task, but if it’s not done correctly, it can cause lasting issues for your system.

Some problems can occur with improper usage of the clean in place (CIP) system or through not applying the right cleaning solutions. There are plenty of options when it comes to cleaning your RO membranes. The best way is determined by analyzing your water and your system operations.

Periodic cleaning can be performed at just the right time, flow rate, and temperature, and it can still fail if the chemistry applied is not appropriate for the specific foulant. For that reason, it is wise to spend some time before a chemical cleaning is needed to determine your most likely membrane fouling.

For example, increased pressure drops in the first stage indicate colloidal from either inorganics or organic fouling in a system, and it can also indicate bacterial fouling. This type of fouling tends to benefit from a low pH soak followed by an alkaline cleaning. If the final stage pressure drops are elevated, it is an indication of mineral deposition. To properly address this type of fouling, it is necessary to know what minerals are most likely to deposit. System projections or antiscalant projections can be useful here, as can a new mineral analysis on both the feed and concentrate. These types of deposits may require low-pH cleaners for carbonate scales or alkaline chelant cleaners for sulfate scales.

At Complete Water Solutions, our technicians have more than 400 hours working with reverse osmosis systems. They can identify contaminants causing membrane inefficiencies and work to treat them safely and effectively. We offer both on-site and off-site cleaning procedures for your convenience. RO membrane cleaning is an essential service we provide to keep your system running smoothly.

On-Site RO Membrane Cleaning Services

Many Industrial Reverse Osmosis Systems are equipped with a CIP or Clean in Place system. This will allow you the ability to clean your Reverse Osmosis system on-site without removing all of your membranes.

This style of membrane cleaning can be beneficial because it reduces your overall downtime. Your system only has to be shut down for as long as the cleaning takes, and can be restarted right away.

If your system is not equipped with a CIP system, Complete Water Solutions can provide and install one that will work with your existing industrial RO system.

FREE RO Membrane Cleaning Log

Off-Site Membrane Cleaning Services

In the lean environment, it is frequently becoming more cost-effective to remove RO membranes and ship them offsite for foulant removal than it is to perform a CIP. Besides sometimes being more cost-effective and less time-consuming, there are additional benefits.

Do not wait until it is too late!

This is what happens when you wait too long – Pictured here is a GE AK4040 AK90 Membrane that was in service for far too long without cleaning. This membrane is no longer serviceable and will need to be replaced. Do not wait too long before getting RO membrane cleaning completed.

No Chemicals Handled or Stored Onsite

Since the membranes are cleaned offsite, there are no chemical risks associated with cleaning the membranes.

More Time

Cleaning membranes offsite allows for more time to soak membranes or clean them multiple times to ensure the removal of hard to clean foulants.

Membrane Replacement Savings

By cleaning membranes off-site, we are able to identify the bad membranes individually and allow you the opportunity to replace them if needed. This can be massive cost savings vs replacing all the membranes in a housing or machine due to bad/failed water quality.

Visual Inspection

By removing the membranes, we are able to visually inspect the housings and membranes to determine if there are any additional problems that could be future failures or quality issues.

Customized Cleaning

By logging serial numbers of membranes and the housings they came from, and having a complete water analysis completed, we can help come up with a customized cleaning program that will help ensure a successful cleaning.

FREE RO Membrane Cleaning Log

Keeping accurate records on past cleanings helps you to better anticipate when your membrane will need its next treatment. Complete Water Solutions provides a free RO membrane cleaning log to help you easily document the details of your membrane cleaning.

Chemicals Used for Industrial RO Membrane Cleaning and Treatment

As mentioned above, one of the benefits of using an off-site cleaning service is not having chemicals in your facility that could potentially damage or contaminate your products. Complete Water Solutions uses a variety of chemicals to treat and clean your reverse osmosis membrane.

The types of chemicals and cleaners we use to treat your membrane will depend on what foulants we find when we inspect your system. The most common chemicals used for maintaining reverse osmosis membranes include:

- Coagulants and flocculants: Substances in this category are applied to pretreatment systems to make contaminants stick together for easier filtration.

- Antiscalants: These chemicals remove any current scaling foulants and inhibit future scaling.

- Antimicrobials: We use membrane-safe antimicrobial chemicals to control microbiological contamination levels.

- Specially formulated cleaners: We’ll create multicomponent cleaners for deep cleaning based on the specific foulants detected in your system.

Industrial Reverse Osmosis Parts

Complete Water Solutions carries a wide array of RO parts in stock. Many we can offer with same or next day shipping! We even carry some obsolete parts in stock, so no matter what your needs are, give us a call or email today to see if we have it.

- Reverse Osmosis Pumps

- Reverse Osmosis Membrane Cleaning Chemicals

- Reverse Osmosis Membranes (All Major Brands)

- Pre-Filters (Cartridge, or Bag Filters)

- UF Modules

- Solenoid Valves

- Conductivity Probes

- pH Probes

- Flow Meters (Signet, Osmonics, and Rotameters)

- Sample Ports

- Butterfly Valves

- UV Bulbs, Sleeves, O-rings, Ballast

- End Cap O-rings & Snap Rings

- Inter-connectors

- Membrane Brine Seals

- End Cap Adapters

- Pressure Gauges

- PLC & Controllers

- Motor Starters

Industrial Reverse Osmosis Membrane Autopsy

Complete Water Solutions provides a range of services specifically designed to identify the causes of membrane failure in Industrial Reverse Osmosis, Nanofiltration and Ultrafiltration Systems. Complete Water Solutions can provide three levels of autopsies depending on the nature of the problem and the level of detail you require:

Level 1 – Deposit / Foulant Identification

Level 2 – Deposit / Foulant Identification Membrane Characterization – Salt Rejection & Flux Oxidation and Integrity Testing

Level 3 – Deposit / Foulant Identification Membrane Characterization – Salt Rejection & Flux Oxidation and Integrity Testing Cleaning Test – Identification of optimum cleaning chemical, dosage, contact time, and pH for foulant removal. Complete Water Solutions team has years of experience with membrane cleaning. We can also carry out plant audits and provide onsite cleaning/troubleshooting assistance.

Additional RO System Services

Complete Water Solutions is not just an RO membrane cleaning company — we offer a range of services to establish and maintain your reverse osmosis water treatment system from start to finish. We’ll help you design a custom system to meet your water production requirements, install it correctly and provide routine maintenance to keep it running.

Once your equipment is installed, we’ll show you exactly how to use it and provide 24/7 tech support in case you come across any issues. We also offer round-the-clock emergency repairs to quickly get your system back to work after a breakdown.

The Complete Water Solutions Difference

Our team at Complete Water Solutions has over four decades of combined experience providing and maintaining custom reverse osmosis water treatment solutions to customers all over the world. Our highly trained technicians learn new technologies and techniques every day to keep your equipment performing reliably.

When you work with Complete Water Solutions, you take advantage of the following benefits:

- Industry-leading products: We provide the top products from well-known manufacturers like Veolia, Osmonics and more.

- Paperless documentation: Our online customer portal gives you easy access to documents like membrane cleaning logs.

- Educational resources: We’ve compiled a free online resource library for you.

- Hands-on customer support: Every client gets the same level of unmatched customer care.

Find out more about Complete Water Solutions’ RO membrane cleaning services by contacting us online.

SCHEDULE RO MEMBRANE CLEANING SERVICES TODAY