Contaminants in My Industrial Water: What to Test For?

When it comes to your business, no matter what industrial operation you’re running, water quality isn’t just an important factor. It’s essential. Whether it’s boilers, cooling towers, manufacturing lines, or sanitation systems, your water quality has a direct affect on the performance and safety of your equipment. Poor water quality can lead to a variety of issues. So, in there lies the question: what contaminants should I be testing for in my industrial water supply?

Having a good understanding of what is in your industrial water supply is a great first step toward protecting your equipment and maintaining your operations at a normal pace. So let’s look into what goes into your water, why it matters, issues that contaminants can cause, and how you can manage them.

Total Dissolved Solids (TDS)

What are total dissolved solids? Better known as TDS, total dissolved solids are the combined amount of inorganic and organic substances that have dissolved within your water. This could be minerals, salts, or metals. There’s a certain level of TDS that is considered normal, but having higher concentrations can interfere with not only your water quality but also your equipment performance.

Water Hardness

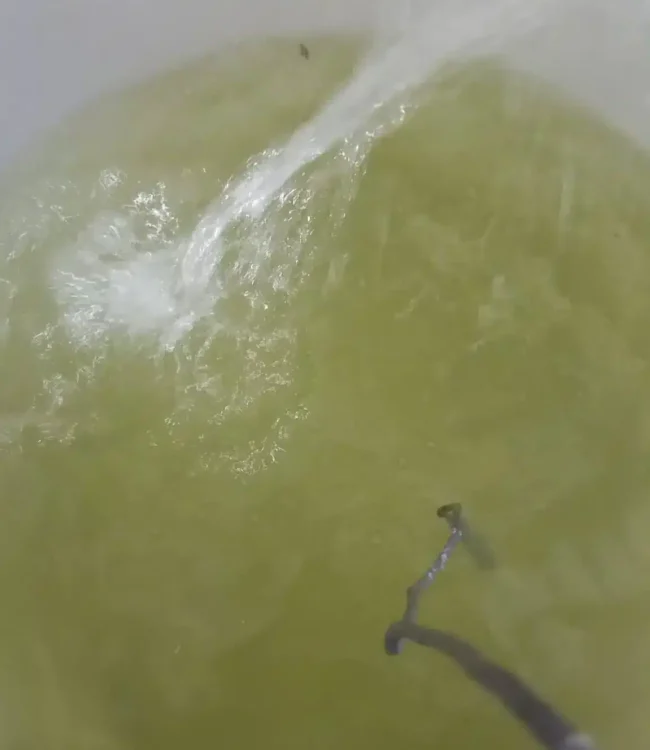

Having too much calcium or magnesium ions in your water can lead to hardness in your water. This is commonly found in groundwater sources, but they tend to cause problems when they gather inside industrial systems.

Silica

Another natural occurring mineral is silica.This can be found in both surface and groundwater supplies. If you’re working with high-pressure boilers or turbines, silica can be a major issue. Even the slightest level of silica can begin to accumulate over time which can lead to a variety of issues.

Iron and Manganese

Iron and manganese are perceived as metals that may not be harmful in small amounts, but just like silica, with build up over time they can cause significant issues.They can enter your water system through corroding pipes and lead to clogged filter and biofouling.

Chlorides and Sulfates

These naturally occurring salts can be corrosive to metal pipes and other system components of your industrial business. Any type of corrosion caused from these can lead to leaks and equipment failures, which of course leads to an increase in your maintenance costs.

Bacteria, Algae, Fungi

Any industrial water system can become the perfect place for bacteria’s, algae, and fungi’s to grow. With the presence of these microbiological contaminants, you can find yourself with a reduction of water flow, damaged equipment, and even a higher risk of corrosion occurring. Some microbiological contaminants can even contribute to metal corrosion directly.

pH & Alkalinity

We’ve all heard of pH balance and alkalinity, but you might not know how large of a role it plays in your industrial water systems day to day functionality. Having the proper balance and monitoring these levels is a basic, yet essential, part of your water treatment. Without proper care, this it yet but another contaminant that can cause corrosion within your system.

How Do You Avoid These Problems?

When it comes to avoiding contamination in your industrial water system, there’s a range of treatments and strategies, and oftentimes, it involves a combination of a few! Reverse osmosis and deionization are typically seen to help reduce dissolved solids, silica, and other minerals that have dissolved within your water supply. If you’re experiencing hardness within your water, water softeners or chemical treatments are most likely the most effective route to take.

With such a heavy portion of these contaminants having a corrosive effect, having targeted filtration or corrosion inhibitors could be the right solution for your business. Regular and consistent testing and monitoring of your water system can help with microbiological contaminants, while maintaining the proper pH and alkalinity levels with a balancing system can help stabilize your water.

Not sure where to start with checking your water supply for contaminants? The team at Complete Water Solutions is here to help. We’ll help you with a custom treatment strategy that can include all of the above, and more! Don’t wait before it’s too late. Preventive maintenance is a great way to avoid downtime and other potential issues. Get in touch with our team today for more information on how we can help you with identifying and solving any issues your water supply might have with contaminants.

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com