USP Purified Water System Maintenance And Sanitization

USP Purified Water is not something industrial facilities can afford to overlook. In pharmaceutical manufacturing, food and beverage production, and laboratory environments, water purity directly impacts product quality, regulatory compliance, and operational continuity. Yet many facilities operate under the assumption that once a USP Purified Water system is installed, it will continue performing indefinitely. That assumption can be costly.

USP Purified Water system maintenance and sanitization are not optional tasks. They are ongoing requirements that protect your process, your reputation, and your bottom line. At Complete Water Solutions, we work with industrial operations nationwide that depend on consistent, compliant purified water. When maintenance is delayed or sanitization is performed incorrectly, the consequences often surface when it is already too late.

What Is USP Purified Water and Why Maintenance Matters

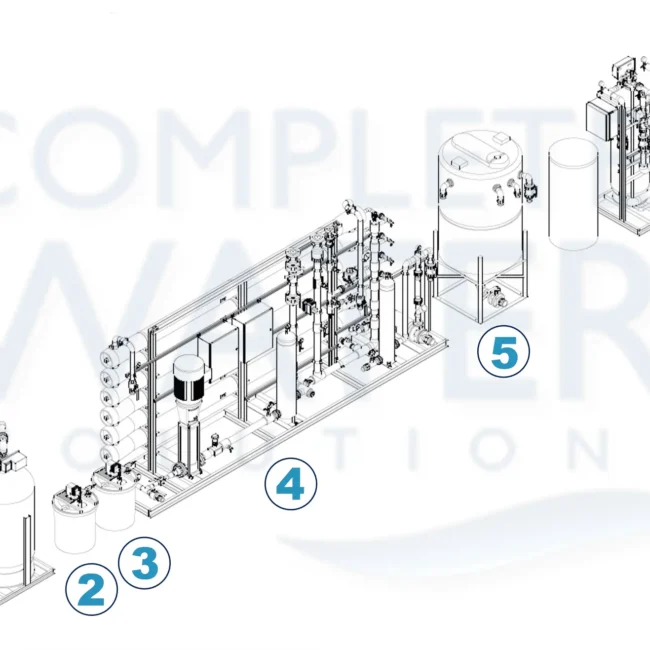

USP Purified Water is defined by strict United States Pharmacopeia standards for conductivity, Total Organic Carbon, and microbial control. It is commonly used as a process water, cleaning agent, and ingredient in non parenteral pharmaceutical products, as well as in laboratory and hygienic manufacturing environments.

What many facilities underestimate is how quickly a compliant system can fall out of specification without proper water system maintenance. Biofilm development, membrane fouling, sanitizer degradation, and component wear can all compromise water quality long before visible system failure occurs.

USP compliance is not a one-time achievement. It is a condition that must be continuously maintained.

The Hidden Risks of Inadequate Water System Maintenance

Even high quality systems are vulnerable when maintenance is inconsistent or reactive. Common risks we encounter include:

-

Gradual microbial growth inside distribution loops

-

Membrane degradation reducing rejection rates

-

Incomplete or ineffective sanitization cycles

-

Undetected component failures affecting conductivity and TOC

-

Documentation gaps that raise red flags during audits

These issues often develop silently. By the time water quality tests fail or production is impacted, facilities may already be facing downtime, batch loss, or regulatory scrutiny.

This is why proactive water system maintenance is critical for any operation relying on USP Purified Water.

Why Sanitization Is a Critical Part of USP Purified Water Systems

Sanitization is not just a checkbox. It is one of the most important safeguards against microbial contamination in USP Purified Water systems. Improper sanitization practices can actually increase risk by disrupting biofilm without fully removing it.

Effective sanitization requires:

-

Correct chemical selection or heat sanitization protocols

-

Proper contact time and temperature control

-

Verification testing following each sanitization event

-

Skilled technicians who understand system design and materials

At Complete Water Solutions, sanitization procedures are tailored to your system configuration and application. A generic approach can leave critical areas untreated and expose your operation to unnecessary risk.

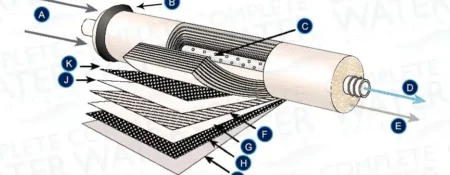

How Reverse Osmosis Membranes Impact USP Purified Water Quality

Reverse osmosis membranes are the backbone of most USP Purified Water systems. Over time, membranes foul, degrade, or lose efficiency due to scaling, organics, or microbial activity. Left unaddressed, this directly affects water quality and system reliability.

Regular membrane inspection, cleaning, and performance tracking are essential components of water system maintenance. In some cases, older membrane models are discontinued, requiring knowledgeable replacement recommendations to maintain compliance and performance.

Complete Water Solutions services and supplies membranes from leading manufacturers such as Veolia, Toray, Osmonics, and Pentair. Our team helps facilities navigate replacements and upgrades without disrupting operations.

Regulatory Pressure and the Cost of Non Compliance

USP standards exist to protect patients, consumers, and manufacturers. Falling out of compliance can result in:

-

Failed audits and inspections

-

Production delays or shutdowns

-

Product rejection or recalls

-

Loss of customer trust

Many facilities only realize the importance of proactive USP Purified Water maintenance after experiencing one of these events. At that point, corrective action is more expensive, more disruptive, and more urgent.

Preventive maintenance is not just about system health. It is about risk management.

Why Industrial Facilities Choose Complete Water Solutions

Complete Water Solutions works exclusively with commercial and industrial operations nationwide. We understand the demands of regulated environments and the consequences of water system failure.

Our approach includes:

-

Comprehensive system assessments

-

Preventative water system maintenance programs

-

USP focused sanitization procedures

-

Emergency service and rapid response

-

Detailed documentation to support compliance

With over 50 years of combined experience, our technicians know what early warning signs to look for and how to address them before they become operational threats.

Proactive Maintenance Versus Emergency Response

Emergency service is sometimes unavoidable. However, most system failures we respond to could have been prevented with proactive maintenance.

Facilities that invest in routine water system maintenance benefit from:

-

Reduced downtime

-

Longer equipment life

-

More stable water quality

-

Fewer compliance surprises

Complete Water Solutions offers scheduled maintenance programs designed around your production schedule, not the other way around. This ensures your USP Purified Water system supports your operation rather than putting it at risk.

Is Your USP Purified Water System Still Protecting Your Operation

If your system has not been professionally inspected, sanitized, or performance tested recently, there may already be issues developing beneath the surface. Water systems rarely fail suddenly. They decline quietly.

The question is not whether maintenance is needed. It is whether you will address it proactively or under pressure.

Work With Experts Who Understand What Is at Stake

USP Purified Water system maintenance and sanitization demand experience, precision, and accountability. Complete Water Solutions is not just a service provider. We are a long-term partner for industrial operations that cannot afford uncertainty.

If your facility relies on USP Purified Water, now is the time to ensure your system is operating safely, efficiently, and in full compliance.

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com