Success Story: Metal Coating Equipment Manufacturer in IL

When a metal coating equipment manufacturer in Illinois faced critical production challenges due to underperforming water purification systems, Complete Water Solutions delivered a seamless, cost-effective solution through a DI Exchange Tank Service and a full turnkey system upgrade.

The Challenge: Failing Water Systems Threatened Production Quality

This customer manufactures precision metal coating equipment used across multiple industries. High-purity water is essential in their process, both for hot water testing and for cooling UV lamps within the machinery. To maintain top performance and prevent scale buildup, the customer required water quality of 1 microsiemen or better.

However, the company’s existing setup relied on five Millipore EMD Elix 100 RO/EDI units, and the system was failing. Two units were leaking, and even when fully operational, the output totaled just 2.2 gallons per minute (GPM) at 77°F. Seasonal temperature drops further reduced production capacity, and upcoming process expansions required an additional 1 to 1.5 GPM of pure water.

The cost of purchasing and repairing additional Millipore units would have been significant, between $67,200 and $112,000, not including installation or maintenance.

The Requirements: No Downtime During System Upgrade

In addition to restoring reliable water production, the customer had a crucial requirement: all installation work had to be completed without disrupting operations. Production could not stop, even during the system transition.

The Complete Water Solutions Approach

To meet these demands, Complete Water Solutions designed and implemented a turnkey industrial water system tailored to the manufacturer’s needs. The solution included:

-

Performa Carbon Filtration System for chlorine removal

-

GE Osmonics E4-6600-DLX (Part #1234818) reverse osmosis unit

-

Electronic Deionization (EDI) system for high-purity polishing

-

New sonic level sensor and wastewater reclaim system to optimize efficiency

But the real game-changer came during installation. To keep the facility running without interruption, Complete Water Solutions provided a Temporary DI Exchange Tank Service. This temporary setup maintained consistent high-purity water supply throughout the demo and installation phases.

The result? The customer didn’t miss a single drop of water.

The Results: Improved Output and Major Cost Savings

After the upgrade, the new system achieved impressive results:

-

Output: 3.5 GPM of DI water

-

Quality: 0.04 – 0.06 microsiemens (16–18 ohms)

-

Savings: Estimated $37,200 – $82,000, excluding installation and ongoing maintenance savings

With Complete Water Solutions, the manufacturer not only restored reliable water performance but also exceeded previous system specifications — all while staying within budget and maintaining production uptime.

Why DI Exchange Tank Service Matters

For industrial facilities that rely on high-purity water, a DI Exchange Tank Service can be a critical bridge during system repairs, upgrades, or emergency situations. It allows continuous operations while maintaining required water quality standards.

In this case, the service provided flexibility and ensured uninterrupted testing and cooling operations. This approach is particularly valuable for industries such as:

-

Beverage Manufacturing (e.g., Pepsi, Coca-Cola, Dr Pepper)

-

Pharmaceutical and Animal Health Manufacturing (e.g., Baxter, Abbott)

-

Food Manufacturing (e.g., Johnsonville, canned goods)

-

Power Generation and Mining Operations

Whether for planned system upgrades or unexpected failures, DI exchange tank solutions provide cost-effective, temporary access to high-purity water without the expense of permanent equipment downtime.

A Trusted Partner for Industrial Water Solutions

From reverse osmosis and EDI systems to emergency DI tank services, Complete Water Solutions helps industrial clients across the country maintain consistent water quality and reliability.

If your facility is experiencing challenges with aging water treatment equipment or you need temporary high-purity water support, our experts are ready to help.

Contact Complete Water Solutions today to discuss your water treatment needs or to learn how a DI Exchange Tank Service can keep your operations running smoothly.

Millipore EMD Elix Machine

Millipore EMD Elix Machine Close-up

GE Osmonics E4-6600-DLX

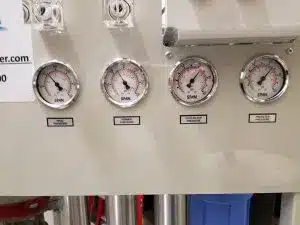

GE Osmonics E4-6600-DLX Gauges

GE Osmonics E4-6600-DLX Intricate System

GE Osmonics E4-6600-DLX/EDI

GE Osmonics E4-6600-DLX Gauges

GE Osmonics E4-6600-DLX Gauges

GE Osmonics E4-6600-DLX Controller

GE Osmonics E4-6600-DLX

GE Osmonics E4-6600-DLX

GE Osmonics E4-6600-DLX Tanks

Need help with your water system?

Contact Complete Water Solutions today!

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com