What is Membrane Fouling and How Can You Prevent It

If you work in manufacturing, you’ve probably heard about membrane technology. It’s a growing industry as it can help you boost quality and cut down on manufacturing costs. Membrane technology is revolutionizing manufacturing by improving water filtration and cutting costs. With the global market projected to grow at a CAGR of 6.5%, from $7.38 billion in 2022 to $11.46 billion by 2029, more businesses are turning to membrane solutions for efficiency. However, membrane fouling can threaten the performance and lead to costly downtime. Let’s explore what membrane fouling is and how you can prevent it to keep your operations running smoothly.

What is Membrane Fouling?

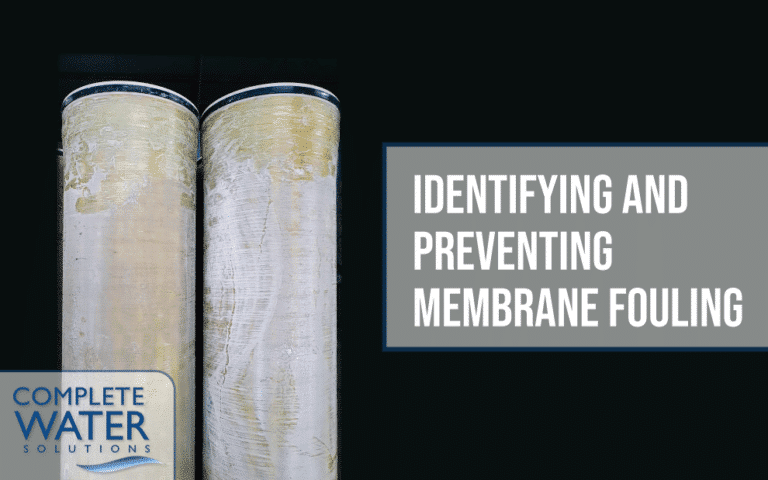

So, “What is membrane fouling”? Simply put, membrane fouling is a process where there are deposits of buildup that reduce both the functionality and efficiency of operating systems. Membrane fouling occurs by the deposition and accumulation of undesirable materials (i.e., organic compound, inorganic compound, or a combination of both) on membrane surfaces. As mentioned above, this reduces the function of your membrane systems, but it can also contaminate the membrane production system. Don’t worry though, as “Membrane fouling is a common issue for all of the membrane-based water and wastewater treatment technologies.

Types of Membrane Fouling and How it Happens

- Colloidal/Particulate Fouling – Suspended solids or colloidal materials are left on the surface or in the spacers of the membrane

- Microbial/Biological Fouling – Fouling – plants, algae living, and microorganisms grow on the surface of the membrane

- Precipitation or Scaling – Soluble salts concentrate and show up in the brine stream of a reverse osmosis system

- Organic Fouling – Carbon-based materials are collected on top of the membrane or in its feed spacer

- Temperature – When temperature limits are exceeded, thermal damage occurs for the membrane, leaving it generally useless. – complete water

-

- Range: The absolute maximum temperature limit for cellulose acetate membranes is 35 degrees Celsius. If are working with most thin film composites, the temperature maximum is 45 degrees Celsius

- Anything above these two thresholds will result in the complete loss of the membrane

- Range: The absolute maximum temperature limit for cellulose acetate membranes is 35 degrees Celsius. If are working with most thin film composites, the temperature maximum is 45 degrees Celsius

How to Prevent Membrane Fouling

Preventing membrane fouling is a lot easier than it may seem. One solution to preventing membrane fouling is to test pH and ionic level strength to minimize absorption. The longer the fouling process allows absorption, the more dire the consequences. Simply testing the pH level or ionic levels in your systems can ensure that your systems are not producing buildups. You can also remove large molecule particles by utilizing a pre-filtration system. This approach can be less hands-on than testing the different levels in your systems, meaning you and your team can maintain the same level of production! Lastly, you can prevent membrane fouling by simply increasing transmembrane pressure to increase flux and reduce membrane fouling. This is only helpful if your system has been partially fouled. The slight increase can still help to restore some of the flux if this is the case.

Your One-Way Stop for Membrane Fouling Solutions With Complete Water Solutions

You want to make sure that your systems are always running efficiently. Membrane fouling is probably bound to happen, regardless of the precautions you take, but being on top of spotting membrane fouling can make or break how much you can produce in a day. At the end of the day, there are some relatively easy ways to prevent membrane fouling. If you are looking for water testing solutions or filtration systems to help you prevent membrane fouling, contact our team at Complete Water Solutions. We would be happy to walk you through the best option for you and your company!

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com