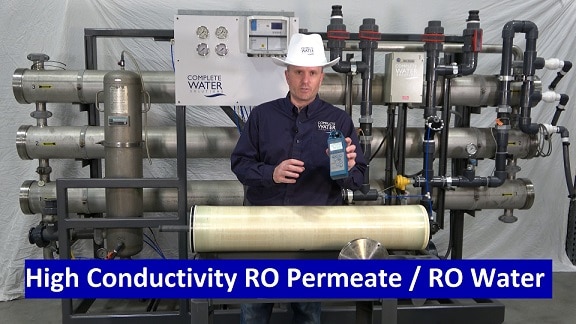

Why Do I Have High Conductivity In RO Permeate Water?

In this RO Troubleshooting video, we investigate some reasons why you may be experiencing high conductivity in your RO Permeate water. High conductivity in RO permeate is not really a desired product, most RO membranes should remove between 97% to 99.5% Total Dissolved Solids (Conductivity). These conductive solids are rejected and disposed of by the waste stream coming off the RO System, also known as concentrate. In this video we discuss areas to check including:

- Brine Seals

- Inner Connector Seals

- End Adapter Seals

We also discuss how to further pinpoint the location of the high conductivity.

RO Troubleshooting Video Transcript

Hi Nathan with CWS. Up next in our troubleshooting series is high permeate conductivity. Now there can be several reasons for high permeate conductivity. If you’ve cleaned your RO membranes and you’re still experiencing high conductivity, or it’s past the 3-5 year mark you may want to look at just replacing it.

Hi Nathan with CWS. Up next in our troubleshooting series is high permeate conductivity. Now there can be several reasons for high permeate conductivity. If you’ve cleaned your RO membranes and you’re still experiencing high conductivity, or it’s past the 3-5 year mark you may want to look at just replacing it.

One of the things you can look at from a troubleshooting standpoint, maybe you just replaced your RO membranes and you’re having high conductivity, is to look at your brine seals- make sure they haven’t rolled or damaged on you. And the end is your permeate adapters, these are your interconnectors, on a 4 inch RO membrane they are going to be couplings, but these O rings if you haven’t replaced them or maybe they rolled on you those are some spots to check. Another area to look at is the end cap at the end of most RO housing. Some of these end caps will have test supports on them, and you can use your conductivity handheld to check your conductivity off of each housing to determine which housing has membranes that are having issues or need replace.

Last thing you may want to check is your incoming water. Your incoming water can fluctuate. Every once in a while it could come from a different source, they could be flushing hydrants, etc, but checking your incoming water supply to see if the conductivity remains the same. If everything’s the same, I definitely recommend cleaning your RO membranes, looking for replacement, or checking your RO membranes.

Need More RO Troubleshooting?

Our RO Experts are standing by!

(855) 787-4200 info@complete-water.com

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com