Industrial RO System: Sizing the System Appropriately

22 Degree x 1.5% = 33%

57,000 Gallons Per Day – 33% = 38,190 Gallons Per Day or 26.52 Gallons Per Minute

Pre-Heat Feed Water

One of the most common ways to achieve this is using a heat exchanger or blending valve to raise the temperature of the water to 77 Degrees F or the most optimum temperature.

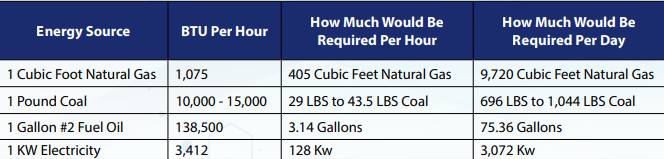

Let’s look at some estimates of energy usage.

Water weighs 8.33 pounds per gallon so we can calculate that one gallon of water requires 8.33 BTU to raise the temperature 1ºF. If we’re using the example above to calculate how many BTUs it would take to raise the water (RO Output of 57,000 GPD) from 55 Degrees F to 77 Degrees F.

57,000 Gallons Of Water x 22 Degrees x 8.33 BTU (8.33 Pounds Per Gallon) = 10,445,820 BTUs

10,445,820 BTU’s ÷ 24 Hours = 435,242.5 BTU’s Per Hour

In the chart below, we break that down into how much of an energy source you’d need, natural gas coal, fuel oil, or KW electricity.

As you can see pre-heating the water can consume quite a bit of energy, which equals a lot of money. It may not be the most cost-effective for your business.

Using Low-Energy Membranes (Cold Water Membranes)

One of the most common alternatives to pre-heating the water is using Low-Energy membranes (commonly known as Cold Water Membranes). Low-energy membranes will produce the same amount of water as standard membranes but at a lower pressure.

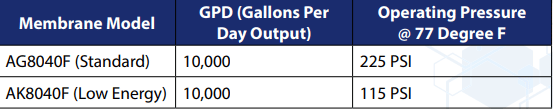

Let’s take a look at a common example of an 8” Standard and Low-Energy Membrane.

At first glance, the AK8040F membrane operates at a lower pressure at 77 Degrees F. This helps save energy as you would not need as large of a pump/motor to deliver the 115 PSI @ 77 Degrees F. Are you wondering how do low energy membranes work in cold water? As the water gets colder, it’s more dense/viscous and thus harder to push through a membrane. So, we use the Low Energy membrane and increase the pressure. This is done by running the AK8040F (Low Energy Membrane) @ 225 PSI vs the 115 PSI. This increase in pressure helps keep the production at the 10,000 GPD output. The energy savings goes away in the form of the smaller pump, but you reclaim that back in fuel savings to pre-heat the water. Low-Energy/Cold Water Membranes are one of the most common options when sizing a RO system for water lower than 77 Degrees F (25 Degrees C).

Size The System Larger

This is likely the least common option, but still a utilized option. Earlier, we discovered that you can lose up to 1.5% (RO Production) per degree lower than 77 Degrees F (25 Degrees C). Moving from 77 Degrees to 55 Degrees F, we lost 33% of Production or 13 Gallons Per Minute Difference on a 57,000 GPD Machine.

Let’s look at the example below on sizing a system for 55 Degrees F using standard AG8040F Membranes:

57,000 GPD @ 77 Degrees F

38,190 GPD @ 55 Degrees F

18,810 GPD Short

We would need an 86,000 GPD RO Machine

86,000 – 33% = 57,620 GPD (Its pretty close)

Strictly speaking, this option is usually not the most economical. It would require you to size your feed water pumps, pre-treatment, and other ancillary equipment for the larger flow. You would also have more wastewater when you go with a larger system. When you contact Complete Water Systems, we can provide guidance on when a larger system might be beneficial.

Trust CWS When It’s Time to Purchase an RO System

Industrial RO System: Sizing Help from Complete Water

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com