Osmo Bev RO/UF/NF Membrane Change Out Services

Complete Water Solutions recently was awarded a contract with a Beverage Manufacture to replace their RO, UF, & NF filter elements. Complete Water Solutions was able to complete this work on a weekend (Sunday) after hours to help minimize down time & production loss. We understand the importance of using Food Grade Products, including lubricants when installing new elements. We take extra per-cautions when working in Food, Beverage and pharmaceutical plants as we understand the extreme importance of cross contamination including allergens.

Osmo Bev RO/UF/NF Membrane Change Services from Complete Water

Before changing RO/UF/NF Membrane and filter elements we will take pre change data. Such data may include, Pressures, flows, conductivity (overall and each housing), turbidity, chlorine, hardness, iron, pH and more. This helps establish the current base line of the machines operating condition.

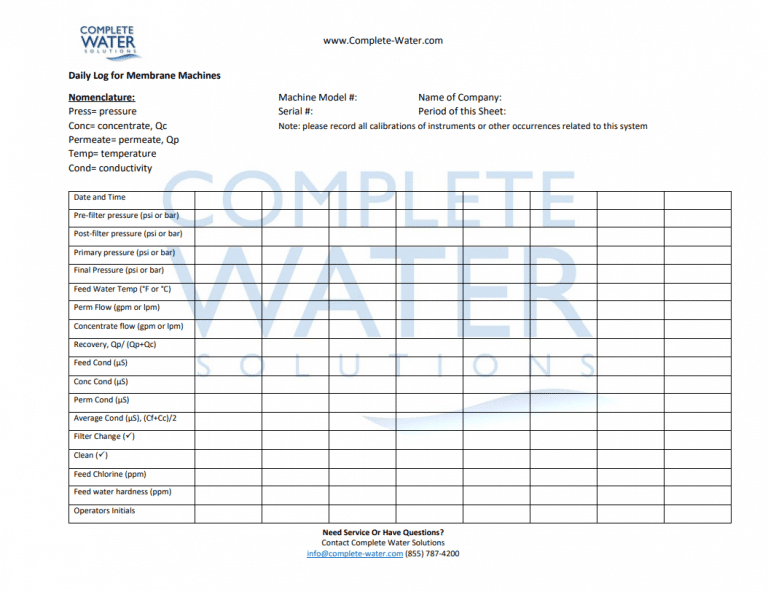

Also we will review the Daily Log which should include this data as well. (need a daily log? click here)

Next we will lock out & tag out the water treatment equipment. And begin to remove the end caps.

When removing the end caps we will replace the end cap o-rings during this time.

The membranes / elements will be visually inspected at this time and notes will be taken.

On this particular element change out we have pulled one filter element in the last housing to be autopsied. (learn more about membrane autopsy service)

Before installing the new membranes Complete Water Solutions log’s each serial number of each element and marks its installation location. This is done to help identify where the membrane is located and if there is to be a warranty claim we will no more about the operation of this filter element. (Membrane Warranty)

After installing the new filter elements Complete Water Solutions will start up the system and begin to take post start up data. Similar to the items tested and recorded prior to taking the system off line to change the membranes / elements will be completed again. This time Complete Water Solutions will fill out a RO start up sheet along with recording in the daily log.

What is a membrane autopsy?

A membrane autopsy helps identify the reason of performance loss. The report will also provide recommendations or best course of action to help correct the problems that caused the failure. Also included in the report are recommended cleaners and procedures to help get the best recovery on your elements.

The autopsy services may include:

Reverse Osmosis Membrane White Sludge (Scale)

- Wet Test

- External Inspection

- Internal Visual Exam

- Foulant Analysis

o Organic

o Inorganic

o Lab Cleaning Study

o Chromatic Elemental

o Identify Damage

Learn The Difference Between Full Fit & Fiberglass Membranes

OSMO-BEV-RO-FF

The elements that were replaced in this RO System were Osmo-Bev-RO-FF Membranes. These Membranes Are Specifically designed for Beverage and Bottled Water Production

The OSMO BEV membrane elements are engineered to provide beverage plants production water with a very high degree of total dissolved solids (TDS) removal, which is often required when producing purified water, very low and sodium free products, and carbonated soft drinks. The OSMO BEV Reverse Osmosis Membranes will produce treated water with lower levels of hardness, alkalinity, sodium and chloride, and is also the element of choice on high TDS feed-water streams.

Osmo Bev RO Data Sheet 1233032

| Model Number | OSMO-BEV-RO-FF |

| Average Permeate GPD | 10,000 |

| Average NaCL Rejection | 99.00% |

| Minimum NaCL Rejection | 98.50% |

| Active Area | 365 SqFt |

| Typical Operating PSI | 200 psi |

| Typical Operating Flux | 10-20 GFD |

| Maximum Operating PSI | 600 psi |

| Maximum Temp | Continuous 122 F |

| Clean In Place 122 F | |

| Minimum Crossflow | 30 PGM |

| pH Range | Continuous 2.0-11.0 |

| Clean In Place 1.0-13.0 | |

| Maximum Pressure Drop | Over an Element 12 psi |

| Per Housing 50 psi | |

| Chlorine Tolerance | 1,000 PPM Hours |

| dechlorination recommended | |

| Feedwater | NTU <1 |

| SID <5 | |

| Part Number | 1233032 |

OSMO-BEV-UF-FF

The elements that were replaced in this UF System were Osmo-Bev-UF-FF Elements. These Elements Are Specifically designed for Beverage and Bottled Water Production. The OSMO BEV UF element creates an absolute barrier to cryptosporidium, giardia, and re-jects color, and organics (naturally occurring tannins, humics, fulvics, etc.). The OSMO BEV UF element offers true multiple barrier security with the lowest energy consumption. It has a nominal MWCO of 6,000Da

Osmo-BEV-UF-FF Data Sheet 1233034

| Model Number | OSMO-BEV-UF-FF |

| Active Area | 350 SqFt |

| Typical Operating PSI | 30-60 psi |

| Typical Operating Flux | 10-20 GFD |

| Maximum Operating PSI | 450 psi |

| Maximum Temp | Continuous 122 F |

| Clean In Place 122 F | |

| Minimum Crossflow | 30 PGM |

| pH Range | Continuous 4.0-11.0 |

| Clean In Place 1.0-13.0 | |

| Maximum Pressure Drop | Over an Element 12 psi |

| Per Housing 50 psi | |

| Chlorine Tolerance | 5,000 PPM Days |

| Feedwater | NTU <1 |

| SID <5 | |

| Part Number | 1233034 |

Contact Complete Water Solutions for your Osmo Bev RO / UF / NF Needs

(855) 787-4200 email info@complete-water.com

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com