New Reverse Osmosis System For Food Manufacturer

Complete Water Solutions recently provided a new water treatment system to replace an old GE Water E4H Reverse Osmosis System with a new LT8-6 Reverse Osmosis System. The new system was selected based on the opportunity to clean membranes on site (Clean In Place), as well as automation control. Additionally, there is an opportunity to expand the system in the future should they need to do so. This project took 4 days start to finish to complete.

The Equipment Provided

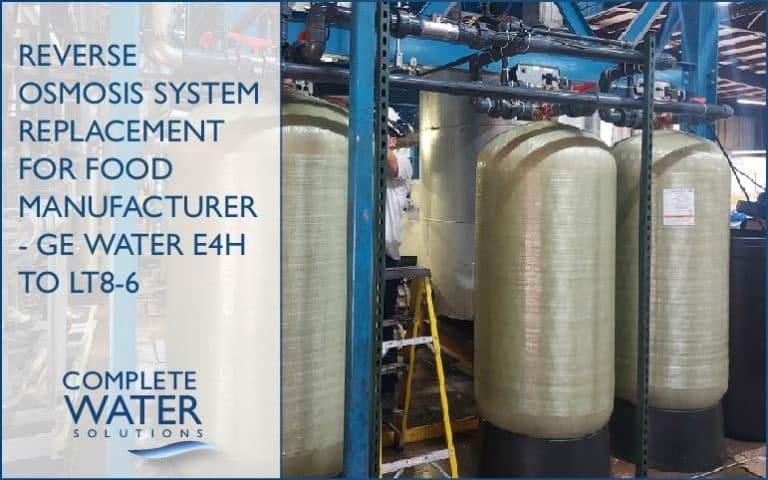

Softener System – CWSI-450-2 Twin Alternating Softener System

The softener system is used to help with hardness reduction by providing soft water. RO (Reverse Osmosis) Systems need either soft water or chemical treatment to prevent scaling on the RO Membranes. Complete Water Solutions provided the CWSI-450-2 Twin Alternating Softener System. The multiple tank design offers a modular platform with several configuration options that brings a customized water treatment plan that fits most demands. The corrosion resistant fiberglass reinforced polyethylene tank design and reliable top mounted valve will provide many years of service.

-

Fleck 2900 Softener Control valve

-

30″ x 72″ Fiberglass Media Tanks

-

15 Cubic Feet Standard Softener Resin

-

30″ x 50″ Brine Tank Assembly

Carbon Filter – CF 36 Single Carbon Filter

The carbon filter system is put in place to reduce chlorine and TOC (total organic carbon) before the RO System. Chlorine, if left untreated, can cause damage to your RO Membranes. The Complete Water Solutions carbon filter come with the following:

- 36″ x 72″ Fiberglass Media Tanks

- Fleck 3150 Backwashing Valve

- 20 Cubic Feet of Media

Reverse Osmosis System – LT8-6 DLX

The Reverse Osmosis System is used as the primary source of filtered water for the process. The RO System reduces the TDS (Total Dissolved Solids) which is suitable for production. The equipment selected and provided for this product was the LT8-6 Reverse Osmosis System. The components of the system include the following:

- Tonkaflo Pump Main Feed Pump

- Fiberglass High Flow RO Pre Filter Housing ROZ-HF-01-40

- Fiberglass RO Membrane Housings 3 Long

- AK8040F-400 Reverse Osmosis Membranes – Six of them

- PLC Controller with HMI

- Inlet pH Sensor

- Pressure Transmitters

- Inlet Conductivity Sensor

- Permeate & Concentrate Flow Transmitters

- Inlet Pressure Switch

- CIP System – Clean In Place

- Hoses

- Tank

- Pump

The CIP System will allow the customer to clean the RO Membranes onsite. This will save them both time and resources versus replacing the membranes.

The Project Timeline

Let us Help you with your water system needs

Are you not sure where to start your Reverse Osmosis journey? Contact Complete Water Solutions for your water system equipment and service needs. Our team has years of experience when it comes to installing industrial systems and are with you every step of the way. We care about the quality of your water, and our team is here for you with repairs or maintenance to keep you running.