How To Take DI Resin Samples & What The Test Will Tell You

Access to clean and purified water is a critical factor for success in a variety of industries, including everything from pharmaceuticals to electronics manufacturing.

Although clean water is something everyone needs, it cannot be achieved without proper purification steps. Deionization, often abbreviated as DI, is a commonly used purification process that eliminates dissolved solids and ionized minerals from water supplies.

Although deionization is crucial to ensuring your water is safe, it is just as important to take care of your DI system to make sure it is effectively purifying your system. To properly care for your DI system, you should be regularly resting your deionization resin by taking samples and sending them away for analysis. This blog will dive into the process of how to take your own DI resin samples as well as what insights that test will give you so you can stay ahead of the game to protect your business.

Understanding Deionization

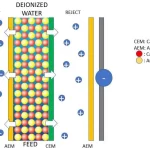

Deionization is a convenient and cost-effective water purification process that uses ion exchange processes to remove charged particles from your water. Essentially, it works by replacing positively and negatively charged ions with hydrogen and hydroxyl ions, which changes the chemical composition of the particles in the water, resulting in formation of purified water. It is critical that deionization is occurring in your water softening system to ensure that there are no dangerous contaminants present that may compromise the quality and safety of your business’s products and processes

Deionization is a convenient and cost-effective water purification process that uses ion exchange processes to remove charged particles from your water. Essentially, it works by replacing positively and negatively charged ions with hydrogen and hydroxyl ions, which changes the chemical composition of the particles in the water, resulting in formation of purified water. It is critical that deionization is occurring in your water softening system to ensure that there are no dangerous contaminants present that may compromise the quality and safety of your business’s products and processes

How Deionization Resin Works

One of the key elements in the process of deionization is deionization resin. The resin is made up of small plastic beads that are either positively or negatively charged. The DI process uses these oppositely charged resins to test for contam inanats. The positively charged resin attracts cations including calcium, magnesium, and sodium, which are contaminants you do NOT want in your water, and it releases an equivalent amount of hydrogen ions into the water. Similarly, the negatively charged resin absorbs unwanted anions including chlorides, sulfates, and nitrates then replaces them with hydroxide ions. These hydrogen and hydroxide ions combine with one another to produce truly purified water (free of contaminants).

inanats. The positively charged resin attracts cations including calcium, magnesium, and sodium, which are contaminants you do NOT want in your water, and it releases an equivalent amount of hydrogen ions into the water. Similarly, the negatively charged resin absorbs unwanted anions including chlorides, sulfates, and nitrates then replaces them with hydroxide ions. These hydrogen and hydroxide ions combine with one another to produce truly purified water (free of contaminants).

Taking DI Resin Samples: Step-By-Step Guide

If ensuring that deionizing is happening in your water softener is something that you’re worried about, you can test the effectiveness of your water softener by following the steps on how to take a DI Resin Sample below:

- Protect Yourself: Before you take any resin samples on your own, you must ensure that you’re wearing the appropriate protective equipment to prevent yourself from touching unwanted contaminants. At a minimum, always wear safety goggles and gloves.

- Prepare your equipment: You’ll need a sample container to hold the resin and a piece of pipe that is about half the depth of your tank. Depending on the size and shape of your tank, you may also need a screwdriver to remove the top and access the resin.

- Take the Core Sample & Extract the Resin: First, you will extract a core sample from the resin using the piece of pipe. Put the pipe into the resin as far down as it can go. Put your hand on top of the end of the pipe to capture the resin and some liquid inside of it. Make sure that you are going deep enough into the tank so that you go beyond just the top of the resin. Dust and dirt can pile up on the top of the resin, which will dilute the reading and provide an inaccurate report. Additionally, if the tank is large, you should consider using a ball valve at the top of the pipe to make your extraction easier. Once you have extracted the resin, you will move it to a separate jar. To get the most accurate reading on the test, you will want to fill the jar up as much as possible with the resin. This can occasionally take drawing a few core samples to complete.

- Lab Analysis: You will then send the collected sample to a lab for analysis. Within a short period of time, you’ll have your results back with the details on what types of contaminants you might have. Depending on those results there are a number of cleaning solutions to repurify your water. While we suggest that you complete this analysis every couple of years, depending on the industry your business is in, you may want to complete it a bit more frequently.

Why You Should Perform DI Resin Tests

At Complete Water Solutions, we highly suggest completing a DI resin test every few years, but regularly scheduled testing offers several benefits. First, it will provide you with insight on any maintenance your water softening system will need. If only trace levels of contaminants are found in your test, then you can get ahead of the game and take preventative actions against those contaminants. It also detects the contaminants that affect your business operations, which allows you to stop production and make sure you’re creating safe products for your customers. Further, this test reveals the water holding capacity of your current system as contaminated resin can reduce the amount that it can hold. If your system has been effected by contaminant build-up, then resolving it can increase your efficiency of production.

At Complete Water Solutions, we highly suggest completing a DI resin test every few years, but regularly scheduled testing offers several benefits. First, it will provide you with insight on any maintenance your water softening system will need. If only trace levels of contaminants are found in your test, then you can get ahead of the game and take preventative actions against those contaminants. It also detects the contaminants that affect your business operations, which allows you to stop production and make sure you’re creating safe products for your customers. Further, this test reveals the water holding capacity of your current system as contaminated resin can reduce the amount that it can hold. If your system has been effected by contaminant build-up, then resolving it can increase your efficiency of production.

Post-Test Actions

If, after completing this test you realize that there is contamination or decreased system performance, there are a couple of potential solutions. If the resin is heavily contaminated, you can fully replace it to help restore the system to nearly its prime condition. If there is just a bit of contamination and depending on the severity of the contaminate, you can implement chloride or salt reduction to rebalance the water.

In these cases, you should reach out to Complete Water Solutions. Our team of water treatment experts can help you decide which course of action is necessary to restore your system. From integrating one of these more ‘quick fixes’ to installing an entirely new system, Complete Water Solutions is here to help. Contact us today to discuss any questions you might have or to schedule an appointment with a professional. Your water quality matters to us, and we’re here to help you achieve the best results.

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com