What Is Reverse Osmosis (RO) and How Does It Work?

What Is Reverse Osmosis (RO) and How Does It Work?

The direct meaning of reverse osmosis (RO) is the movement of water through a membrane when pressure is applied on one side of the membrane. Reverse osmosis is one of the most effective, economical technologies available for removing a range of impurities from water.

Learn more about reverse osmosis in terms of commercial and industrial uses below!

CONTACT AN EXPERT

Customer Service (Toll-Free)

Table of Contents

- REVERSE OSMOSIS DEFINED

- BENEFITS OF REVERSE OSMOSIS

- CHALLENGES TO CONSIDER WITH REVERSE OSMOSIS

- ABOUT RO MEMBRANES

- HOW DOES REVERSE OSMOSIS WORK?

- HOW DOES AN INDUSTRIAL REVERSE OSMOSIS SYSTEM WORK?

- KEY COMPONENTS OF AN RO SYSTEM

- WHAT CONTAMINANTS WILL REVERSE OSMOSIS REMOVE FROM WATER?

- WHAT IS THE BEST INDUSTRIAL REVERSE OSMOSIS SYSTEM?

REVERSE OSMOSIS DEFINITION

Reverse osmosis is a water filtration technique that uses a thin, semipermeable membrane with tiny pores that admit pure water through while keeping out bigger molecules like ionized dissolved salts and other impurities. Reverse osmosis generates highly purified water and is useful for industrial boilers, drinking water systems, seawater desalination, pharmaceutical production, cosmetics production, food and beverage processing and many other applications.

BENEFITS OF REVERSE OSMOSIS

As a water treatment process, reverse osmosis provides many advantages, including:

- Total dissolved solids reduction: Reverse osmosis is one of the rare water treatment processes that can boast a total dissolved solids reduction. The few other treatment methods with this capability are often less efficient than reverse osmosis.

- Cost-effectiveness: Reverse osmosis is popular in industrial settings because it is highly economical compared with alternative filtration methods. It allows plants to treat large volumes of water while remaining comfortably within their established budgets.

- Eco-friendliness: Compared with other treatment methods, reverse osmosis is also relatively environmentally friendly. It uses less energy than other methods like thermal distillation because it does not rely on energy generation. Using reverse osmosis can help a facility reduce its carbon footprint, protect the environment and do its part to curb climate change.

- Alkalinity and hardness removal: Reverse osmosis removes the calcium and magnesium ions that contribute to hard water, as well as the carbonate ions that contribute to unwanted alkalinity.

CHALLENGES TO CONSIDER WITH REVERSE OSMOSIS

For all its advantages, reverse osmosis also presents a few challenges. Below are a few considerations to keep in mind when you’re working with a reverse osmosis system:

- Waste: Reverse osmosis systems use large volumes of water. Industrial systems tend to handle this issue better than household systems because they can generate the backpressures needed for wastewater recovery. Still, waste is a challenge to consider carefully. Some systems must also limit their wastewater recovery because higher recovery rates can diminish effective contaminant removal rates.

- Mineral removal: RO systems generally target water impurities indiscriminately. Some of the removed solids, including minerals like calcium and magnesium, are beneficial. The treated water may require remineralization so that it will not corrode pipeline infrastructure.

- Waste stream challenges: In most applications, the solvent stream that results from RO processes is waste that requires proper disposal. Facilities must take care to dispose of this waste responsibly and in compliance with the law.

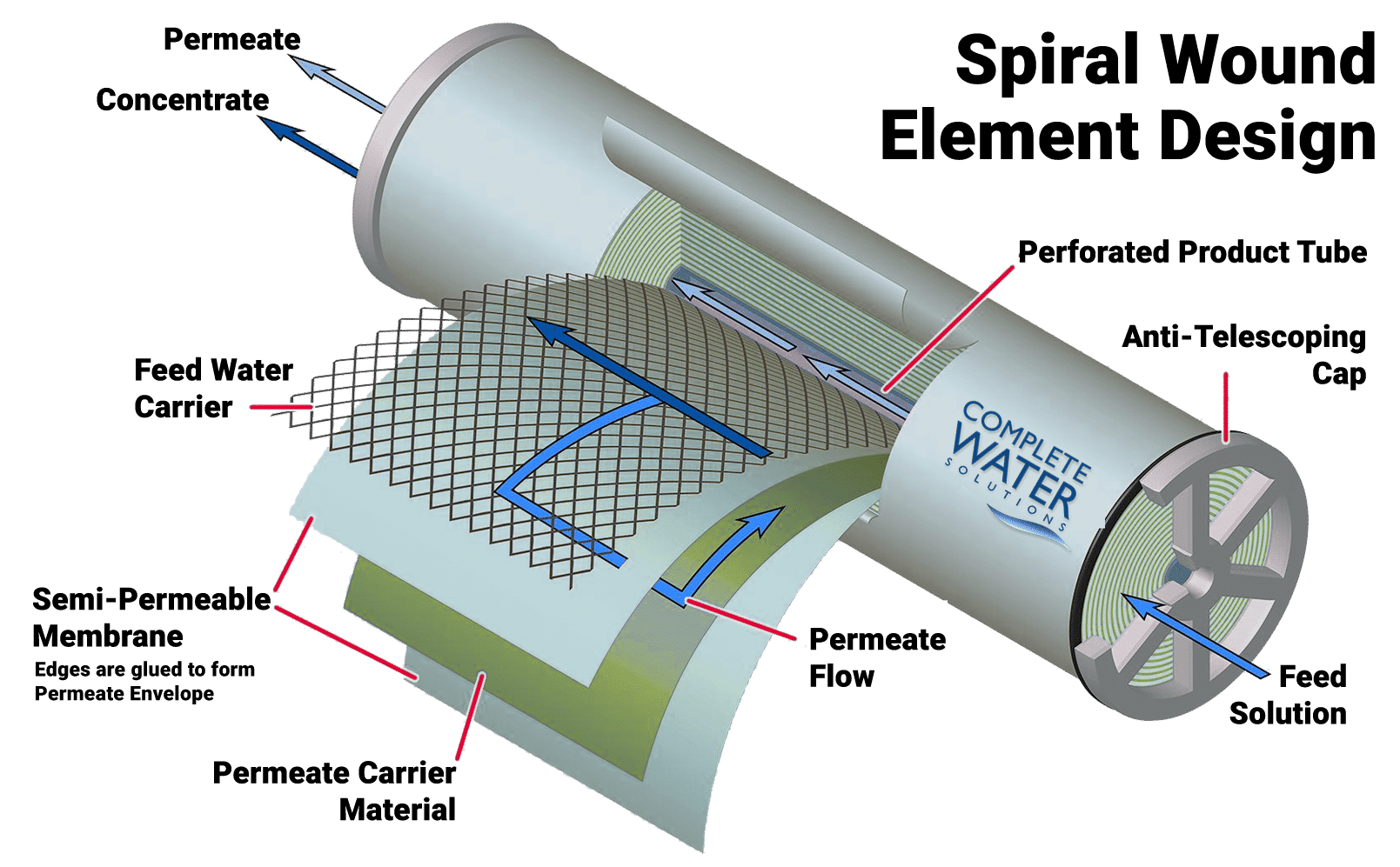

A reverse osmosis system is dependent upon and built around its individual membranes. Each membrane consists of a spiral-wound sheet of semi-permeable material (varies dependent on application). Membranes are available in 2-inch, 4-inch, and 8-inch diameter with the 4- and 8-inch diameter sizes most commonly used in the water treatment industry. The water treatment industry, as a whole, has accepted a 40-inch length as a standard size so that membranes from different manufacturers are interchangeable in equipment systems. One of the primary measurements of a membrane is its square footage. Membranes are available in the range of 350-450 sq. ft. of surface area.

Semi-permeable membranes were first constructed using cellulose acetate (CA), however, the industry later switched (primarily) to the use of a thin film composite (TFC) being placed on top of a stronger substrate. TFC membranes are primarily used today.

HOW DOES REVERSE OSMOSIS WORK?

Reverse osmosis is a treatment technology with continuous operation that uses pressure to pass source water through a thin membrane and thereby separate impurities from water.

Reverse Osmosis (RO) works by reversing the principle of osmosis, the natural tendency of water with dissolved salts to flow through a membrane from lower to higher salt concentration. This process is found throughout nature. Plants use it to absorb water and nutrients from the soil. In humans and other animals, kidneys use osmosis to absorb water from the blood.

The reverse osmosis principle reverses that process. In a RO system, pressure — usually from a pump— is used to overcome natural osmotic pressure, forcing feedwater with its load of dissolved salts and other impurities through a highly sophisticated, semipermeable membrane that removes a high percentage of the impurities. The product of this process is highly purified water.

The rejected salts and impurities concentrate and collect above the membrane and are passed from the system to drain or on to other processes. In a typical commercial or industrial application, 75% of the feedwater is purified. In applications in which water conservation is important, 85% of the feedwater is purified.

An RO system uses cross-filtration, where the solution crosses the filter with two outlets: the filtered water goes one way and the contaminated water goes another way. To avoid the buildup of contaminants, cross-flow filtration allows water to sweep away contaminant buildup and enough turbulence to keep the membrane’s surface clean.

HOW DOES AN INDUSTRIAL REVERSE OSMOSIS SYSTEM WORK?

If you look at a reverse osmosis diagram for an industrial facility, you may see three to five main stages taking place. A three-stage reverse osmosis system includes a sediment filter, a carbon filter and a semipermeable membrane. These are stages one, two and three, respectively. A four-stage system adds another membrane to filter out particles the first membrane may have missed.

How does a five-stage reverse osmosis system work? A five-stage system sends its water through the same sediment filter, carbon filter and semipermeable membranes. It also adds post-filtration, sending the water through an additional carbon filter to remove any lingering impurities. Some five-stage RO systems also add a remineralization step that returns beneficial minerals to the treated water.

Below are the basic steps of an industrial reverse osmosis system:

- Prefiltration: Reverse osmosis systems have two types of prefilters that filter out larger particles like sediment and chlorine. The water first flows through a sediment prefilter that removes particles like dust, dirt and rust. Then it moves on to flow through an activated carbon prefilter that binds to and removes substances like chlorine and volatile organic compounds (VOCs).

- Reverse osmosis: After prefiltration comes the main event of reverse osmosis. At this stage, the pump sends the water through the semipermeable membrane that traps smaller, harder-to-remove dissolved solid particles. This step of reverse osmosis can often remove the vast majority of the dissolved solids in the water.

- Drainage: Once the water has flowed through the semipermeable membrane, the next step is drainage, which sends the removed impurities down the drain. This step is essential because contaminants that build up on the membrane can compromise its effectiveness. Draining the collected impurities keeps the RO system’s efficiency high.

- Storage: The final stage is storing the treated water until its eventual use. The storage container is often a pressurized vessel large enough to contain the treated water without necessitating waste. The treated water may also flow through an additional carbon filter that can remove any stray impurities.

KEY COMPONENTS OF AN RO SYSTEM

Below are the essential components of any reverse osmosis system:

1. RO Membranes

A reverse osmosis system is dependent upon and built around its individual membranes. Each membrane consists of a spiral-wound sheet of semipermeable material, which varies dependent on application. Membranes are available in 2-inch, 4-inch and 8-inch diameter with the 4-inch and 8-inch diameter sizes most commonly used in the water treatment industry.

The water treatment industry, as a whole, has accepted a 40-inch length as a standard size so that membranes from different manufacturers are interchangeable in equipment systems. One of the primary measurements of a membrane is its square footage. Membranes are available in the range of 350-450 square feet of surface area.

Semipermeable membranes were first constructed using cellulose acetate (CA). However, the industry later switched to the use of a thin film composite (TFC) being placed on top of a stronger substrate. TFC membranes are primarily used today.

2. Housings

Individual membranes are loaded into a single housing, which can hold up to six membranes in series. The housings are critical for holding the reverse osmosis filters stably in place. They also connect to the check valves and drain lines that prevent backflow and enable the water to drain effectively.

3. Stages

Housings are then grouped into parallel flow streams called stages. A single reverse osmosis system can have up to three stages in series. The major benefit of using RO stages in series is the reduction of wastewater. In an efficient RO staged system, wastewater can be reduced to 15% of the total flow, whereas the rejection flow from a single membrane alone can be as high as 50%.

4. Pretreatment Cartridge Filtration

A complete RO system will also include a pretreatment cartridge filtration and a pressuring pump. The pretreatment cartridge filters remove larger solids from the water before it proceeds to the semipermeable membrane. This step is necessary to prevent fouling of the membrane and extend its life span.

Cartridge filters tend to be simple constructions and are often made from wound strands of polypropylene.

5. Controls System

A comprehensive RO system also has a controls system. In a small RO system, the controls may be as simple as valves and rotameters. A larger system will contain the flow, temperature and pressure transmitters, as well as control valves operated from a human-machine interface (HMI) or programmable logic controller (PLC). Larger systems also incorporate variable frequency drives (VFDs) for the pressurizing pump and sometimes energy recovery devices.

The controls system allows users to monitor and operate the RO system from beginning to end. It also often contains alarms that can notify operators of any RO system issues that require immediate attention.

WHAT CONTAMINANTS WILL REVERSE OSMOSIS REMOVE FROM WATER?

Reverse osmosis can remove a wide range of dissolved solids from water, including the following:

- Arsenic

- Barium

- Calcium

- Chlorine

- Colloids

- Dyes

- Fluoride

- Herbicides

- Lead

- Mercury

- Nickel

- Nitrates

- Proteins

- Pesticides

- Phosphate

- Sediment

- Sodium

- Sulfates

- VOCs

Some reverse osmosis systems can also remove organic contaminants like certain viruses and bacteria from water, though they may not be able to remove 100% of these contaminants.

WHAT IS THE BEST INDUSTRIAL REVERSE OSMOSIS SYSTEM?

For the best in industrial reverse osmosis systems, count on Complete Water Solutions for quality, turnkey systems and quick, convenient access to expert advice.

Our reverse osmosis solutions give you the tools you need to purify your water and reduce alkalinity and water hardness while keeping your costs and energy consumption low. We also pride ourselves on our extensive industry training and expertise — our skilled technicians are highly trained and certified, with many having gone to top RO schools to learn their craft. The benefit for you is that you’ll always have experts to consult with when you have questions about your reverse osmosis system or about which one might be best for your operations.

DEPENDABLE REVERSE OSMOSIS SYSTEMS FROM COMPLETE WATER SOLUTIONS

When you need proven, economical and eco-friendly water treatment, make Complete Water Solutions your trusted source for reverse osmosis systems. Our turnkey systems and service reduce your time and labor expenditures, and our quick customer service means you can often have a resolution to your questions in 30 minutes to an hour. We offer free quotes and 24/7 support, and we are happy to take the time to consult with you about your unique industrial water purification needs.

For more information about reverse osmosis, feel free to contact the RO system experts at Complete Water Solutions, or visit our resource library today! You can also check out our free RO e-book to learn more.

CONTACT US TODAY

Complete Water Solutions

Location:

851 W Main Street

Twin Lakes, WI 53181

Phone: (855) 787-4200

Email: info@complete-water.com