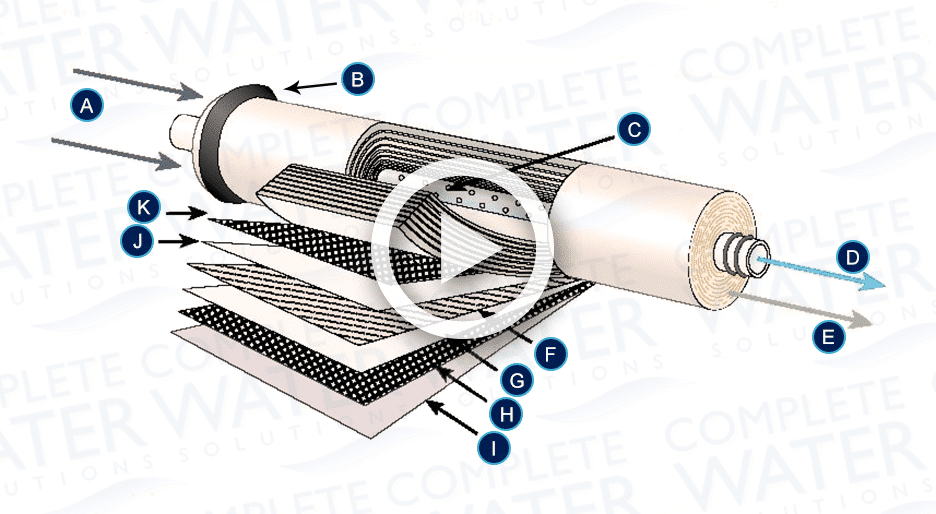

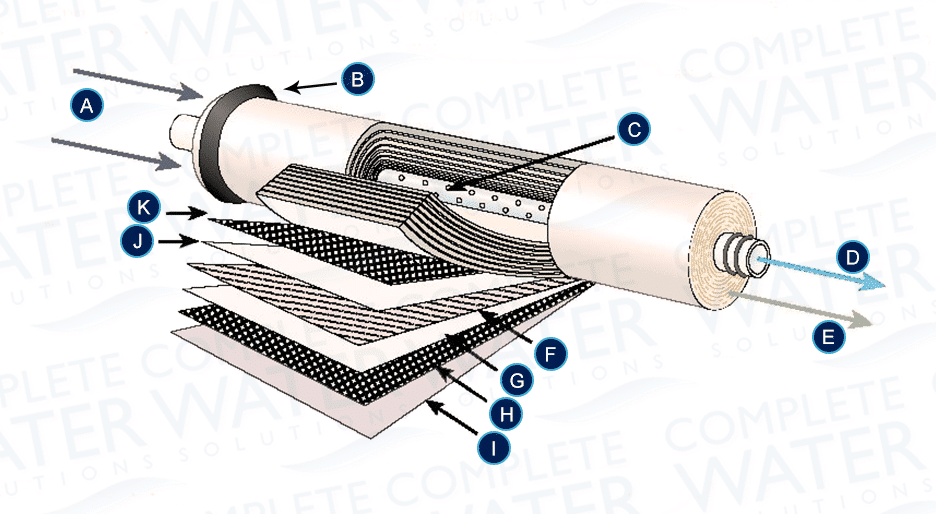

Diagram of Reverse Osmosis (RO) Membrane Elements and Parts

Industrial Reverse Osmosis (RO) Membrane Elements & Parts

Feed Solution

The feed solution is the water source or processing fluid. Prior to reverse osmosis, the feed solution may have been treated with chemicals, passed through pre-filters, or even a UV system. The feed solution varies based on the source of your feed solution.

Brine Seal

Brine seals are plastic or rubber devices that seal one end of the membrane element against the wall of the component housing. This prevents the feed solution from bypassing around the element.

Perforated Central Tube

The perforated tube in the center allows the membrane element to maintain its shape facilitates the passage of water through the parts of the RO membrane element.

Permeate

The permeate is the final and desired “product” of reverse osmosis filtration. The permeate water is sometimes referred to as pure water, or simply “product” water, and usually has 95%-99% of the dissolved salts removed from it.

Concentrate

The concentrate is the undesirable water that exits the membrane element. Sometimes called the “reject” water, it carries the concentrated contaminants that did not pass through the membrane.

Permeate Collection Material

Also known as a “permeate water carrier”, or “mesh spacer”, the collection material is placed between two layers of the flat sheet membrane. Constructed of a knit fabric called “tricot”, it prevents the membrane from closing itself off under pressure and facilitates collection of permeate water.

Reverse Osmosis Membrane

Most RO membranes are thin-film composite (TFC), constructed with a thin polyamide layer atop a polyethersulfone porous layer. In conjunction with the permeate collection material, the membrane has the property of high rejection of undesired materials (like salts).

Feed Channel Spacer

Feed channel spacers are a netting material placed between the flat sheets of a reverse osmosis membrane to promote turbulence in the feed / concentrate stream. This material is referred to as “Vexar.”

Outer Wrap

When treating brackish water, your RO elements will need to have a fiberglass wrap, as higher pressures are needed. However, if treating regular feedwater, a tape outer wrap should suffice. It all depends on your needs!

View more resources to help you learn about reverse osmosis here and contact Complete Water Solutions today with any questions about your industrial reverse osmosis system!