Industrial Reverse Osmosis System New York

New York's Top Industrial Reverse Osmosis System

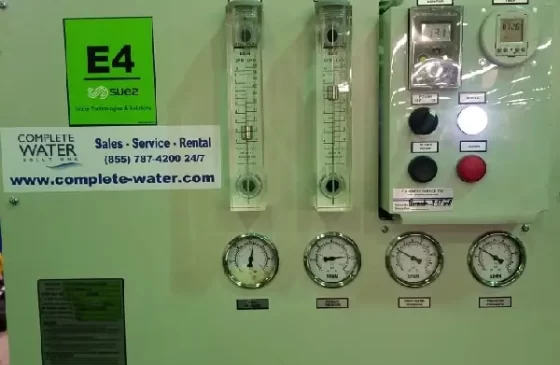

If you are searching for Industrial Reverse Osmosis System New York, Complete Water Solutions is the way to go. We are experts with everything in water treatment and reverse osmosis systems. Not only do we service New York, but we provide for the entire nation! Our team of professionals is Industrial Reverse Osmosis System experts to help maintain your water system. We only use high-quality products, equipment, and services that you would expect from a national corporation. Don’t let that scare you- we still provide the best personal, and hands-on experience. Feel free to take a look below to see how we can help you with your reverse osmosis system.

How can we serve you?

Building engineer check:

We work with the building engineer to learn about the system and its performance. We will also inspect the equipment maintenance log, if available. This allows us to provide you quality Industrial Reverse Osmosis System New York.

Water quality check:

Water is tested for hardness, chlorine leakage, iron, Reverse Osmosis quality, and EDI / CEDI quality.

Exterior system check:

Piping, valves, and tanks will be inspected for leaks, corrosion, or exterior damage.

Report:

We issue a complete report after an inspection, which includes all pertinent data.

Valve operation check on Softeners:

Flow patterns for regeneration and service cycles are checked for proper operation. Each cycle will be started for an abbreviated period:

- Service cycle

- Backwash cycle

- Brine cycle

- Rinse cycle

- Flush cycle

- Manual operation of each cycle to check the pilot spool

- Cam gear and pilot strainer are inspected

- Pressure tubing to valves is inspected.

- System is checked for leaking to drain

Brine system check:

- Brine tank and brine level in the tank are inspected

- Brine valve is inspected

- Brine rinse cycle is timed and checked for depressurization

- Brine draw and rate is observed

Valve operation check on Media Filtration:

Flow patterns for backwashing and service cycles are checked for proper operation. Each cycle will be started for an abbreviated period:

- Service Cycle

- Backwash Cycle

Controls check:

Controls are observed for proper operation and programming. Adjustments are made as needed. Electronic controls are manually stepped through operations and reviewed for proper programming. Re-writing of any program is not included.

Reverse Osmosis:

- A complete report is issued after each inspection, which includes all pertinent data.

- Pump & Motor Check

- Membrane / Prefilter Check

- Pressures are regulated, and adjusted for best possible quality water.

EDI/CEDI:

The Electronic Deionization System is checked for quality, resistivity output, and electrical consumption. All wiring and water connections are checked. Adjustments are made for the best quality water.

Calibration:

Calibration of Probes & Monitors – pH, Conductivity, Resistivity, Hardness, Chlorine, and ORP

Training:

We can provide training on the sequence of operation of the existing system shall be provided for new or existing personnel.

Industrial Reverse Osmosis System Preventative Maintenance contracts can include all parts, service parts, membranes, and pre-filters. We even provide contracts for up to 5 years to include all maintenance items.