Understanding Boiler Operation

Understanding Boiler Operation

One of the most common water softener applications is for softening the supply water to steam boilers. Most industrial and many commercial establishments require steam. Steam is used in textile mills to produce, form, and dye fabrics. The dry cleaner uses steam to iron linens. Canneries and meat packers cook or process foods with steam. Bakeries prepare bread with steam. The breweries use it to make beer. Boilers are used frequently for heating water in hotels, hospitals, laundries, and large buildings. It drives many of the turbines that produce electrical power. As a general rule, the larger the factory or industrial operation, the more apt we are to find one or more steam boilers in operation at that facility.

Steam Production

Most boilers have several things in common. Usually at the bottom is a firebox or combustion chamber (furnace) where the cheapest or most available fuel is fed through a burner to form a flame. The burner is controlled automatically to pass only enough fuel to maintain a desired steam pressure. The flame or heat is directed and distributed to the heating surfaces which are usually tubes, flues, or coils of fairly small diameter. In some designs the water flows through the tubes or coils and the heat is applied to the outside. These are called water-tube boilers. In other boilers, the tubes or flues are immersed in the water and the heat passes through the inside of the tubes. These are fire-tube boilers. If the water is subjected to the heated gases more than once, the boiler is a “two pass,” “three pass,” or “multiple pass” boiler.

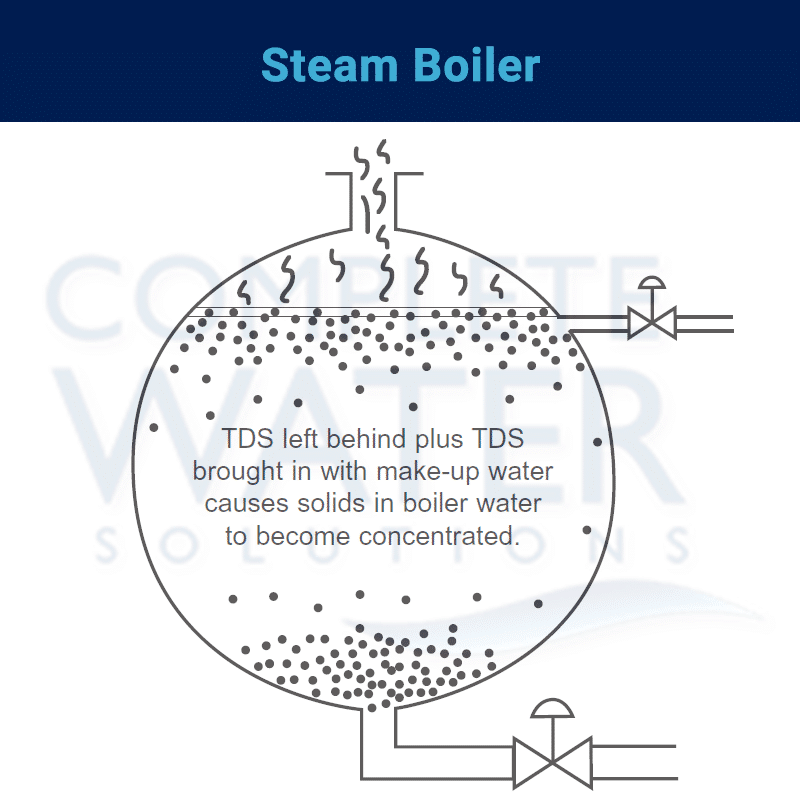

The heated water or steam rises to the water surface, vaporizes, and is collected in one or more chambers or “drums.” The larger the drum capacity, the greater is the ability of the boiler to produce large, sudden demands of steam. At the top of the firebox is a metal or brick chimney or “stack” which carries away the combustion by-products and varying amounts of unused fuel. At the bottom of the boiler, and usually at the opposite end from the firebox, is an outlet valve called a “blowdown.” It is through this valve that most of the dirt, mud, sludge and other undesirable materials are purged from the boiler. Attached to the boiler are a multitude of safety controls to relieve the pressure if it gets too high, to shut off the burner if the water gets too low, or to automatically control the water level. A water column (sight glass) is provided so that the interior water level is visible to the operator. 1

Boiler Feed Water

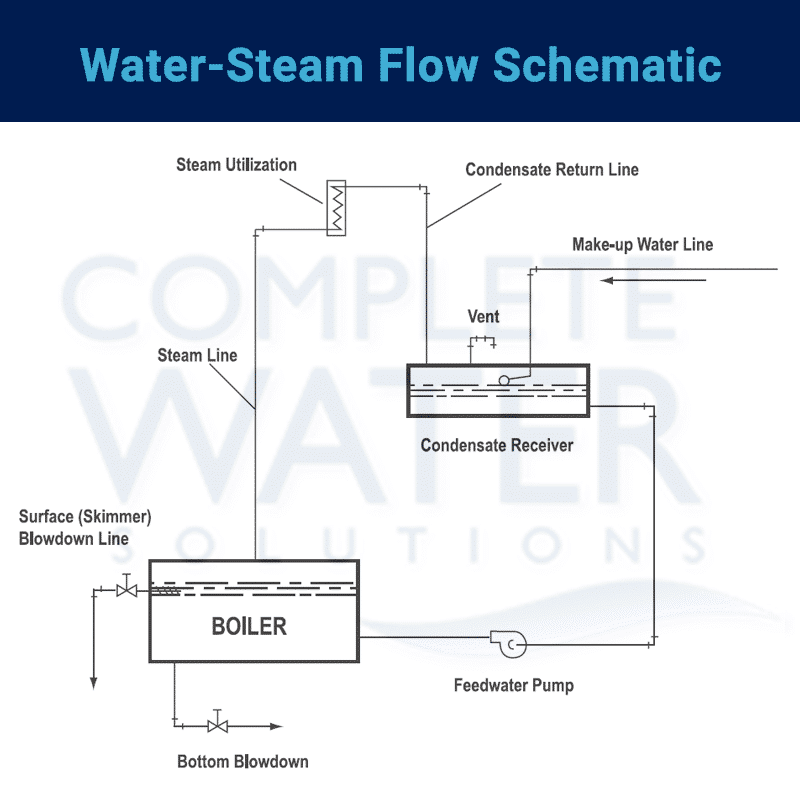

The water for the boiler is usually stored in a “make-up” tank so that a sufficient volume of water is available for larger than usual demands. A constant level is maintained by a float valve similar in principle to the tank type toilet float control. A high pressure pump pulls the water from the make-up tank and pushes it into the boiler. Because most boilers operate at pressures higher than those of the water supply, the pump must raise the feed water pressure to somewhat above that of the boiler operating pressure.

Clean steam is pure water in the form of a gas. When it is cooled and condensed, it is pure water and it is referred to as “condensate.” As it is condensed into water it contains considerable heat which can be utilized. It is nearly perfect boiler make-up or feed water since it has been stripped of dissolved minerals and foreign matter in the evaporation process.

Whenever possible, condensate is returned to the boiler and is collected in a tank called a “condensate receiver.” When condensate is recovered, the receiver may also perform the functions of the make-up tank.

In some installations, condensate return may supply as much as 99% of the feed water and the higher the percentage of condensate the less water treatment is required. Other installations may use 100% make-up if for, various reasons, the condensate cannot be recovered, or if it is badly contaminated.

Boiler Pressures

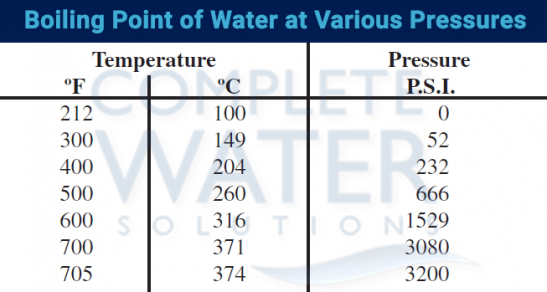

The temperature and pressure at which a boiler operates have a definite relationship as shown in the following table:

At normal atmospheric pressure, water boils at 212ºF (100ºC), at higher pressures the boiling point increases, reaching a maximum of 705ºF (374ºC) at a pressure of 3200 pounds per square inch. Above this temperature water cannot exist as a liquid.

Boiler Ratings

Boilers are rated by the amount of steam they can produce in a certain period of time at a certain temperature. The largest units produce 1,000,000 pounds per hour of steam. Boilers are also rated on a power basis. A boiler is rated at one horsepower for every 34.5 pounds of water it can evaporate per hour. Another definition is one horsepower for every 10 square feet of heating surface in a water-tube boiler or 12 square feet of heating surface in a fire-tube boiler.