The Mechanics of Filtration

The Mechanics of Filtration

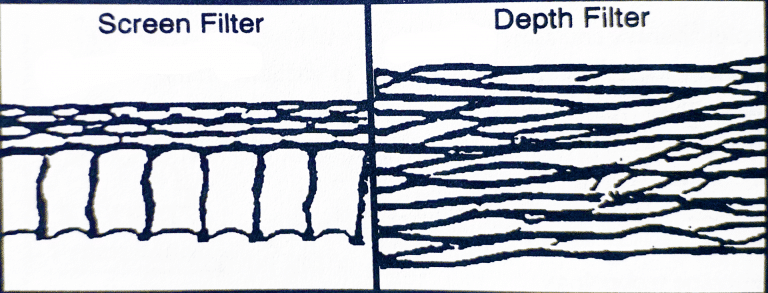

Commercial and industrial filtration systems fall into two broad categories: surface filters and depth filters. Essentially, filtration is accomplished by either surface and depth filters or by electrostatic attraction of undissolved particles in water to certain types of filter media.

Surface (screen) Filtration

Surface filtration can be described as a “straining” technique, somewhat akin to the sifting of flour in baking, where a series of holes or perforations (all the same size) in a flat metal or plastic sheeting can remove particulate from a liquid. This series of surface holes holds back solid particles on the basis of size, allowing those of smaller diameter to pass through.

In this “screening out” process, however, a layer usually will build up on the surface filter and become a secondary filter surface. This surface layer then does the actual filtering – and in so doing establishes a type of “depth filter” element upon the surface filter itself.

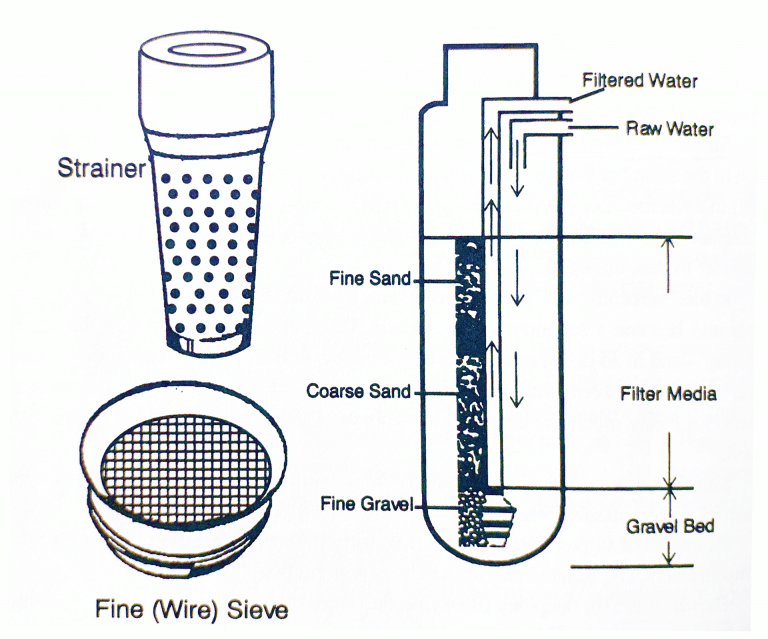

Surface filters can be either strainers with uniform holes or perforations in a rigid material, or certain membranes with uniform, tiny openings. Examples of surface filters (Figure 1-3) that you may run into on a daily basis include Y-strainers, faucet aerator screens, sump strainers, and basket hair catchers in swimming pool filter systems.

Depth Filter (deep-bed)

The tank type filters contain loose media, which form irregular pathways for the water or liquid to pass through. In addition, some media, such as granulated activated carbon, are highly porous particles, offering microfiltration of some microorganic molecules. With the use of more than one layer of medium in filters, the void spaces acan be varied even further. Depth filtration is described as “water [liquid] flowing through a mass filter medium or series of media, following a torturous pathway; with many entrapments” -usually of successively decreasing void spaces through the depth of the filtering bed. In deep-bed depth filters, particulate matter is first deposited in the upper inch or two of the bed. Once the layer of particulate is deposited, additional particles can flow through the irregular maze of channels or paths to be entrapped in locations deeper in the media bed. Examples of deep-bed depth filters include anthracite, sand, and garnet mixed-media systems.

Depth filtration also includes those string-wound and special fabrics (Figure 1-2) used as part of cartridge-style filter units. Some undissolved particulates in water carry a very slight charge; thus, in certain cases, these particles are separated by electrostatic attraction to the filter medium itself.