Introduction to Water Filtration – Part 1

Introduction to Water Filtration - Part 1

Filtration

Filtration is used as an add on to normal coagulation and sedimentation for the elimination of solids from surface water or wastewater. The gets the water ready to use as potable, boiler, or cooling make-up. Wastewater filtration aids users with meeting more demanding effluent discharge permit specifications.

Filtration, typically treated as an uncomplicated mechanical process, actually includes the mechanisms of adsorption (chemical and physical), straining, sedimentation, diffusion, interception, and inertial compaction.

Removal of dissolved solids does not happen during filtration, but when used with a softening process will lower the concentration of dissolved solids. An example would include anthracite filtration being used to remove lingering precipitated firmness salts remaining after clarification in precipitation softening.

Most water softening or clarification processes where precipitation and coagulation happen, a fraction of the clarified water is filtered. Clarifier effluents of 2-10 NTU could be improved to 0.1-1.0 NTU by traditional sand filtration. Filtration provides adequate suspended solids concentrations in the polished water even when issues happen in the clarification processes.

Types of Media

There are several types of filtration material that can be used in filtration. Some of those materials are silica sand, quarts sand, anthracite coal, magnetite, and garnet. Anthracite and silica sand are used most frequently. There are occasions when silica sand is not appropriate. An example would be in a filter that follows a hot process softener where the treated water is designed for boiler feed. In that case, anthracite is typically used.

The shape and size of filter media directly affects the adeptness of the solids removal. Sharp, angular media form large gaps and eliminate less fine material than rounded media of similar size. Using media coarse enough to allow solids to penetrate the bed for 2-4 inches would be ideal. However, many suspended solids are stuck at the surface or in the first 1-2 inches of bed depth, with some penetration to prevent a rapid increase in pressure drop.

Anthracite and sand filters are graded by effective particle size and sameness. The effective size is such that around 10% of all grains by weight are smaller and 90% are larger. The effective size is then the minimum size of most of the particles. Sameness is measured by a comparison of effective size to size at which 60% of the grains by weight are smaller and 40% are larger. When the larger size is divided by the effective size it is called the sameness coefficient-the smaller sameness coefficient, the more identical the media particle sizes.

Finer sands conclude in shallower areas for the retention of suspended matter. The most preferable media size rests on the characteristics of the suspended solids and the effluent quality requirements and the particular filter design. Overall, rapid sand filters use sand with an effective size of 0.35-0.60 mm (0.014-0.024 inches) and a maximum sameness coefficient of 1.7. Coarse media, 0.6-1.0 mm (0.024-0.04 inches), are utilized for closely controlled coagulation and sedimentation.

Typical Construction

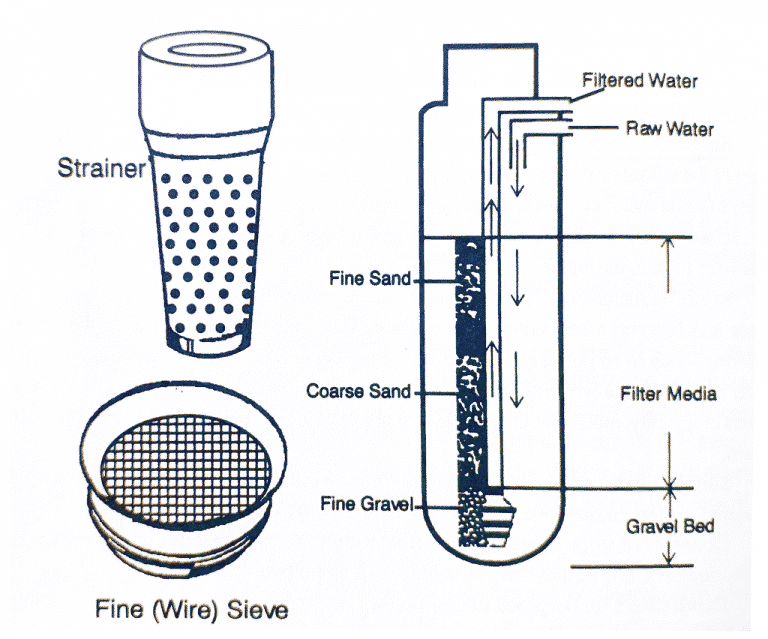

Traditional gravity and pressure rapid filters preform downflow. The filter medium is typically a 15-30 inch deep bed of anthracite or sand, with single or multiple grades being used.

A hefty particle bed supports the filter media to avoid fine anthracite or sand from slipping into the underdrain system. The support bed also helps in distributing backwash water. Normally, support beds are made of 1, 8-1 inch gravel, or anthracite in graded layers to a depth of 12-16 inches.