High Flow Z Depth Filters

High Flow Z Depth Filters

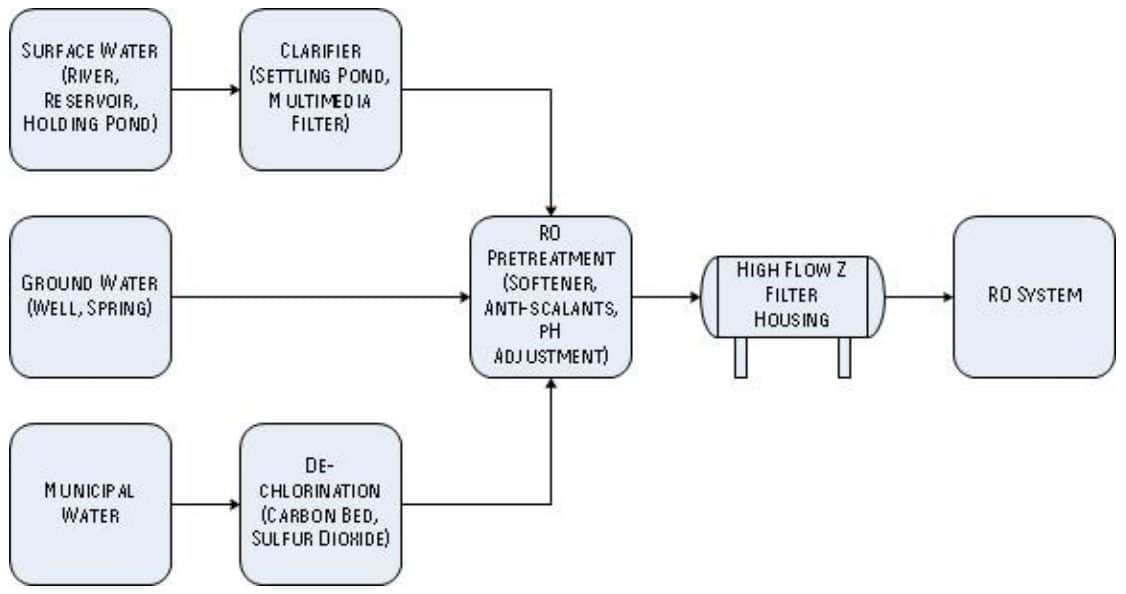

For Reverse Osmosis Pre-treatment

APPLICATION BRIEF

Overview

Many industries use water purified by reverse osmosis (RO) systems for a broad spectrum of applications – from boiler feedwater to ingredient water for consumer products. Every RO system must have the proper pre-treatment system to provide optimum performance and long life. To meet both of these criteria, GE developed the next generation of depth filters for RO pretreatment – High Flow Z. High Flow Z is manufactured using patented Z.Plex filter technology and is engineered for RO prefiltration and other high purity applications. High Flow Z’s proprietary filter matrix provides unmatched performance for RO pre-treatment combing high efficiency with high particle holding capacity, and long life.

Critical to Quality

- FDA compliant and NSF 61 certification

- Lowest total operating cost

- Resistance to sanitizing chemicals

- Elevated temperature resistance

- Local availability and stock of filters

- Long filter life and reliability

- Low maintenance and ease of change out

- Ergonomic design

Challenges

- Sufficient particle retention to prevent membrane fouling

- Wide variety of feed streams (well, seawater, surface water, river)

- High flow volume

Solutions

- HF.Zs filters rated at one micron for optimal particle protection and maximized intervals between membrane cleanings

- HF.Zs filters rated at five microns for maximized filter life where shorter membrane cleaning intervals are not a concern

Benefits

- Each HF.Zs filter can accommodate flows from 60 to 100 gpm (13.6 to 22.7 m3 /h) replacing up to 5 conventional 40-inch cartridge filters on a flow basis (5 gpm or 1.1 m3 /h per TIE).

- Each HF.Zs filter can hold up to 6800g of dirt, equivalent to 60 conventional 40-inch cartridge filters.

- A single HF.Zs filter can have up to 12x longer service life than 5 conventional 40-inch cartridge filters.

Challenge

An RO system with a 700 gpm (159 m3 /h) feed flow requires pre-filtration to protect the membrane elements from fouling. If conventional depth cartridge filters are used, up to 35 forty inch filters (at 5 gpm or 1.14 m3 /h per TIE) may be required!

Solution

HF.Zs filters rated at one micron were selected. A 7- round HF.Z filter housing was selected, resulting in a flow of 100 gpm (22.7 m3 /h) per filter, within the recommended design flow of 60 to 100 gpm (13.6 to 22.7 m3 /h) per filter. At 100 gpm (22.7 m3 /h) per filter, the clean differential pressure associated with the filters was less than 0.5psi. Also, the filters reliably maintained SDI of less than 3.

Benefits

Operating at very low differential pressures, the HF.Zs filters require less energy to operate and reduce wear on the pump. By maintaining SDI of less than 3, the HF.Zs filters provide effective protection of the RO membranes and provide for longer intervals between cleanings. Given the immense amount of dirt holding capacity, the HF.Zs filters exhibit exceptional service life and long intervals between change-outs.

Compared to the alternative of a 35-round filter housing with conventional 40-inch depth cartridge filters, the HF.Zs solution has several distinct advantages which provide the lowest total cost of operations:

- 12X the service life of traditional 40” filters – The HF.Zs solution has 1/10 the clean differential pressure (0.5psi versus 5.0psi). A single HF.Zs filter has about 60 times the dirt holding capacity of a conventional 40-inch depth cartridge filter; consequently, the HF.Zs solution will have about 12x the service life of the conventional filters in the 35-round housing.

- Eliminates concern about filter by-pass – Using filters with a single-open-end design and 226 o-ring fitting, the HF.Zs solution eliminates concerns about filter bypass associated with using conventional double-open-end filters.

- Dramatically reduces labor and overhead costs associated with filter replacement – The conventional filters in the 35 round housing will need to be replaced about 12 times before the HF.Zs filters will need to be replaced. It is a far simpler and shorter task to replace 7 filters when compared to replacing 420 filters!

High Flow Z Filters:

- Low pressure drop

- Excellent dirt holding capacity

- Graded density decreases blinding

- Excellent temperature / oil resistance

- Provides lower total cost of filtration operations

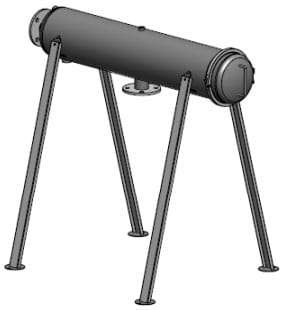

High Flow Z Housings:

- Single, four and seven round housings standard. Larger units available.

- Carbon, 304 and 316 SS and fiberglass versions.

- ASME code stamped standard.

- Additional certifications including PED and CRN

High Flow Z filters provide customers with exceptional filtering with reduced cost. If you would like more information about how High Flow Z filters can provide you with the same, please contact your GE account representative or visit gewater.com.