Getting to Know Cartridge Filters – Part 2

Getting to Know Cartridge Filters – Part 2

Cartridge filters are generally used for prefiltration in pure water systems. In such systems, the makeup water passes through the cartridge filters to remove suspended contaminants rated in the range of one micron and five microns. Cartridge filters have various types of filter media, as shown below.

String-wound Filters

String-wound filters look like a spool of yarn. The “yarn,” or string, is usually made from cotton or polyprpylene fibers. The filter has a core usually made from polypropylene or stainless steel. The core is a pipe with holes onto which the filter medium is attached. In the case of a string-wound filter, the string material is wrapped around the core in a distinct pattern. Usually, the filter is wrapped tighter closer to the core and looser toward the outer part, which allows it to act as a depth filter. Depth filters trap the larger particles on the outer portion of the filter and smaller particles within the filter as the water works its way through a tighter and tighter matrix of fibers. In a depth filter, particles are trapped all the way through the filter matrix and not just on the surface.

Pleated Filters

Pleated filters are made from a tightly woven, fabric-like material or a thin membrane of material that is folded into pleats in order to get a large surface area into a cylinder shape. The fabric, or membrane, can be made from polypropolene, polysulfone, or Teflon. Unlike string-wound filters, pleated filters are usually considered surface filters, in that particles are, for the most part, trapped at the surface of the filter.

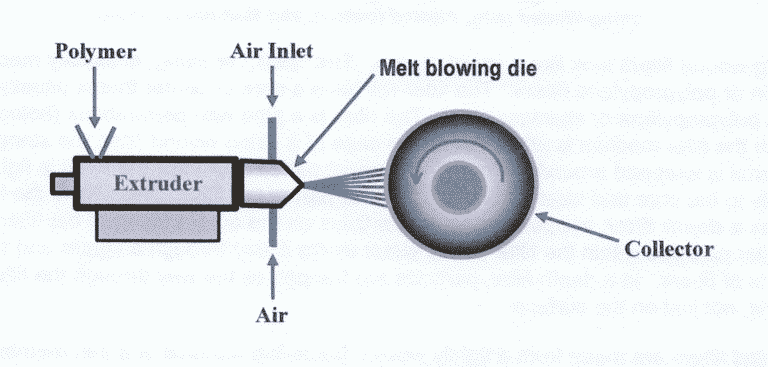

Melt-Blown Filters

Melt-blown filters are made via a special process in which melted polypropylene fibers are blown onto the filter core. Finer fibers are produced closer to the core and coarser fibers towards the outer surface, again creating a depth filters.