Dairy JX Series

February 18, 2020 - Nathan Olszak

Dairy JX Series

Microfiltration – Clarification and Fat Removal

The Dairy JX microfiltration elements are characterized by a nominal pore size of 0.3micron and are low fouling when oils and grease are present. These elements are used for the removal of fat and colloidal impurities in food process streams and are often used in cheese brine clarification. These elements feature a Durasan* Cage patented outer wrap, a selection of feed spacers, and polysulfone parts.

TABLE 1: ELEMENT SPECIFICATION

Membrane J-Series, Polyvinylidene Fluoride

| Model | Spacer mil (mm) | Active area ft2 (m2) | Outer wrap | Part Number |

|---|---|---|---|---|

| DAIRY JX3840C50 | 50 (1.27) | 55 (5.1) | Cage | 1207259 |

| DAIRY JX6338C50 | 50 (1.27) | 168 (15.6) | Cage | 1207269 |

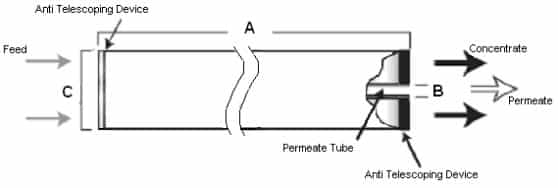

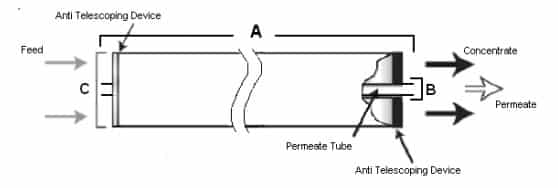

TABLE 2: DIMENSIONS AND WEIGHT

Dimensions, inches (cm) B

| Model1 | A | B | C | Boxed lbs (kg) |

|---|---|---|---|---|

| DAIRY JX3840C50 | 38.75 (98.4) | 0.833 (2.12) | 3.79 (9.6) | 7 (3.2) |

| DAIRY JX6338C50 | 38.0 (96.5) | 1.138 (2.89) | 6.34 (16.1) | 18 (8.2) |

- These elements are bagged dry before shipping

- Internal diameter

- The element diameter (dimension C) is designed for optimum performance in GE pressure vessels. Other pressure vessel dimension and tolerance may result in excessive bypass and loss of capacity.

TABLE 3: OPERATING AND CIP PARAMETERS

| Typical Operating Pressure | 40-100psi (275-689kPa) |

| Typical Operating Flux | 5-20 GFD (8-34 LMH) |

| Maximum Operating Pressure | 100psi (700kPa) |

| Maximum Temperature | Continuous Operation: 122°F (50°C) Clean-In-Place (CIP): 122°F (50°C) |

| pH Range | Continuous Operation: 2.0-10.0 Clean-In-Place (CIP): 1.0-11.5 |

| Maximum Pressure Drop | Over an element: 15psi (103kPa) Per housing: 60psi (414kPa) |

| Chlorine Tolerance | 5,000+ ppm-days |