Cation Water Softener Design

Different Cation Water Softener Designs

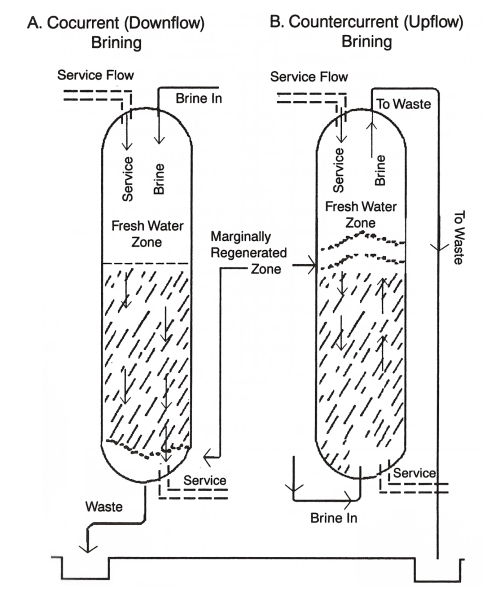

Water softeners for business and commercial/industrial use can be engineered to operate in one of several flow patterns. Broadly speaking, designs are either “cocurrent flow” or “countercurrent flow”. In addition, softeners may be designed for “free-board backwash expansion operation” or in a “contained bed” configuration that does not provide for backwashing.

Cocurrent Flow

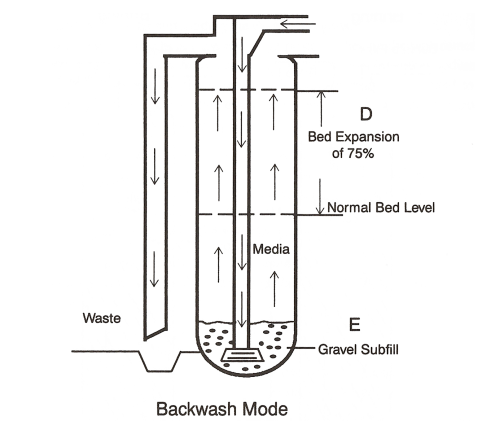

Cocurrent flow (or downflow) mode has been the most widely used design in industrial-size water softeners. In this process, the water being softened flows downward through the cation resin bed (see image below – left), and the brine solution also flows downward to accomplish regeneration. (A variation of the cocurrent flow mode would be a system in which both streams flow upward through the bed.) The cocurrent design calls for less complicated master control valving and also offers the full backwash step to expand the bed (see image below – right) for thorough cleaning when the softener is treating troublesome water supplies, such as those containing turbidity and precipitated iron.

In the cocurrent method of regeneration, the brine solution initially introduced at the top of the tank passes through and then displaces the fresh water zone, thus diluting the strength of the incoming brine at the beginning of the regeneration step. As a result, the bottom layer of the cation resin bed becomes only marginally regenerated at the lower salt levels (3-5 lbs. NaCl/cu ft.). Accordingly, when the softener returns to (downflow) service, some hardness leakage could occur.

Countercurrent Flow

In the second mode of operation, known as countercurrent flow, the service flow and the brining flow are in opposite directions — that is, softening downward through the cation resin and brining upward through the bed. Often called “upflow brining”, this method offers several benefits. In this mode, the strong, less diluted brine solution immediately contacts the lower portion of the resin bed for maximum recharging. Depending upon salt dosage level (lbs./NaCl/cu. ft.) and the corresponding water hardness, the degree of resin bed recharging will vary. However, the counter-flow brining method is especially effective in low salt dosage (3-5 lbs./cu. ft.) demand-regenerated units, because the bottom bed zone is always in the most fully regenerated sodium (Na) or potassium (K) form. In this countercurrent mode, when the softener returns to service flow, the water leaving the softener tank passes through the most highly regenerated region of resin last, assuring maximum softening with relatively little hardness leakage.

To accomplish effective regeneration and capacity with the countercurrent method, special hydraulic engineering steps must be incorporated in the system to hold the cation resin bed in a fixed position during brining. One way this can be accomplished is to brine the resin bed before backwash. This way the cation resin bed is compacted from its downflow service run and less likely to “fluidize”.

A fluidized bed would prevent the brine solution from fully contacting and penetrating (actually passing through) the exchanger beads to accomplish full separation of the hardness ions from the cation resin itself. An essential step in the efficient regeneration of all water softeners is the final “fast rinse”, which effectively removes any residual or lingering salt brine from the resin bed, prior to returning the unit to service.

Countercurrent Industrial Water Softeners

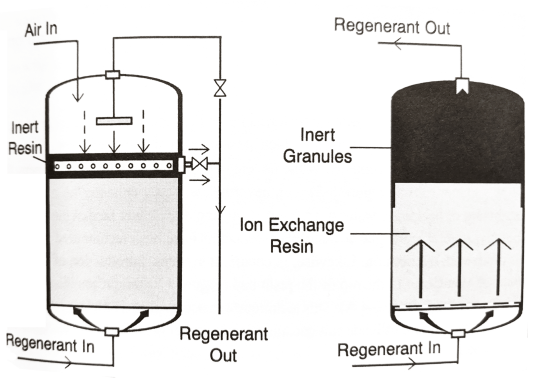

In large industrial cation water softeners, this fixing of the resin bed can be carried out with either compressed air, a second water stream block, or installation of low-density inert plastic granules above the cation bed.

To obtain maximum operating performance and capacity of either a concurrent or a countercurrent flow water softener, each design must incorporate proper internal distribution piping arrangements. While no longer popular in small water softeners, the use of a gravel subfill will, nevertheless, easily enhance the more equal distribution of backwash water or brine solution across the lower face of the resin bed. Recently, several lower plastic distributor-collectors have been recontoured to achieve this more even distribution. Likewise in cocurrent systems, introduction of the strong brine solution closer to the top of the resin bed minimizes dilution in the freshwater zone. This technique can accomplish a stronger regeneration force as well as more efficient salt consumption. Another benefit of this concept is less wastewater.

Twin-Tank Softeners

Another unique concept in commercial and industrial water softener design is the alternating twin-tank scheme. In this system, the cation water softening is accomplished with two identical softener tanks, with a master control mechanism that automatically switches from tank to tank when a predetermined exhaustion point has been reached. Each tank takes over to provide a continuous supply of softened water while the other is taken out of service and regenerated for stand-by status. These twin-tank softening systems are either meter/nonelectric controlled or meter/electric-regenerated systems.

This type of system offers round-the-clock softened water, easily accomodating erratic flow demands. A second advantage is that the brine makeup water is always softened and conditioned, with no hardness or iron getting into the brine-saturator unit. A third feature is that once the twin-tank system is on-line and operating, only softened, conditioned water is admitted to either softener tank for backwash and rinse. This feature eliminates any hardness carryover and/or avoids precipitated iron (where present in the raw water) from contaminating the cation resin bed.