Understanding Different Types of Filter Elements

Understanding Different Types of Filter Elements

While the spectrum of available cartridge elements is very broad, going from coarse grit removal types at 100 micron rating to very fine filter elements of the 1.0 micron rating used for reverse osmosis pretreatment, the bulk of units fall into two major categories: (1) sediment removal and (2) taste and odor (chlorine), organics, and hydrocarbon compounds reduction.

Sediment Filter Elements

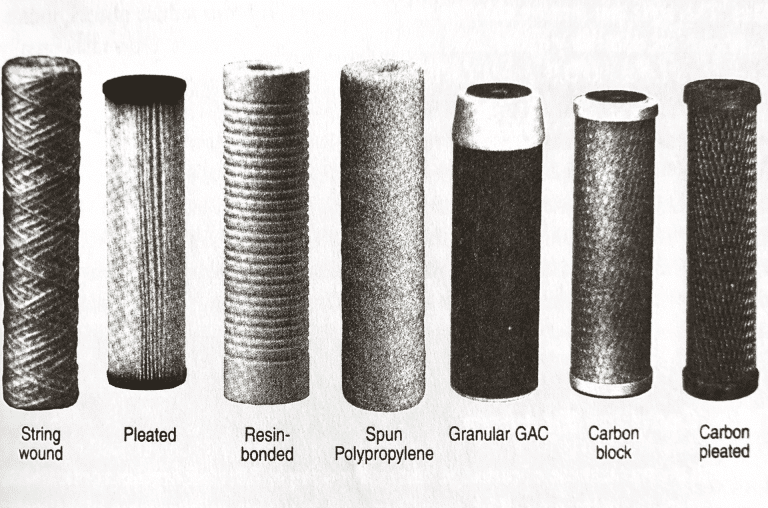

Sediment filter elements (Figure 1-18) follow different basic designs and are manufactured from several different materials, such as:

Pleated impregnated cellulose made from resin-coated paper is the most economical, with very high filter surface area afforded by the pleats–up to 600 square inches. Generally, it has a 20 micron rating and provides up to 5.0 U.S. gpm service flow. It functions as a surface filter and is good for dirt, rust, scale, and fine silt. However, this type is subject to decomposition by cellulose-eating bacteria.

String-wound fiber elements made from either natural or synthetic yarn tightly wound around a perforated core built up in layers create a depth-style filtering element. As such, these have various nominal ratings that can range from 0.5 micron for very fine particulate to 100 micron for coarse undissolved particulate.

Bonded filter elements are made from synthetic or cellulose fabrics that are rolled or cast into a preformed shape, then treated with a resin polymer and cured. It is generally machined to size with grooves added to increase surface area, is usually lower in cost, and available in fine, medium, or coarse micron ratings and is a good general-purpose surface filter element.

The cartridge-style activated carbon medium filters offers multifunctional treatment, just as is done with loose-media bed filters. These elements are capable of sediment removal as well as adsorption of excess chlorine, musty taste, and reduction of many hydrocarbon compounds such as pesticides and other synthetic organic chemicals. Three activated carbon technologies are employed in the design of these cartridge elements: granular, powdered precoat, and powdered block carbon.

Powdered activated carbon, impregnated cellulose units are prepared using powdered activated carbon bonded to pleated filter paper, or from carbon impregnated into a fiber mat. This style can handle medium to moderate levels of particulate matter as well as taste/odor/organics reduction. It functions as a surface filtering device, and service flow can range from 2.5 to 5.0 U.S. gpm for sediment removal. When used for chlorine/organics reduction, service flow rate is generally limited to 2 U.S. gpm.

Granular activated carbon (GAC) elements contain almost one pound of carbon, tightly packed with an out wrap of synthetic fabric or enclosed in a plastic cylinder. The outer wrap acts as a surface filter for sediment, and the packed carbon functions as a depth filter. This style can remove chlorine residuals longer and also reduce phenol, iodine, hydrocarbons, and many undesirable organic chemical compounds. Flow rates usually range from 1.0 to 4.0 U.S. gpm.

Block carbon cartridges are a rather new configuration in disposable filters. Powdered carbon is prepared in a slurry with a binder and then pressed into a preformed shape. The finer carbon offers much higher surface exposure and increases its ability to reduce chemicals. This syle would be classified as a depth filter and a very effective unit for taste/odor/organics reduction; however, it is subject to higher pressure drop than the packed granular carbon units. Block carbon elements should not be used for sediment because of higher costs and the tendency to prematurely plug up. Flow rates are from 1.0 to 3.0 U.S. gpm.

Other Cartridge Elements

Although the greatest use of cartridge units is for straight filter/adsorption applications, several manufacturers now offer cartridges with products to overcome other water problems. Some add chemicals to water, such as polyphosphates, effective for control of scale and corrosion; a combined activated carbon and hexamethaphosphate for taste/odor/scale; manganese greensand for iron removal; and activated alumina for fluoride, arsenic, selenium, and lead reduction.

For special business needs, disposable mix-bed ion exchange cartridges are available, for instance, to deionize water for laboratory-grade quality.