Cation Water Softeners & Controllers

Cation Water Softeners & Controllers

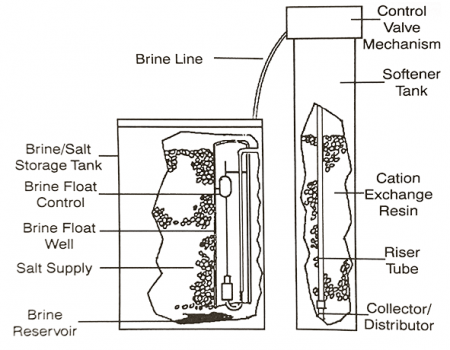

The basic components of cation water softener systems (see image) consist of:

- A pressure vessel (tank) containing a bed of cation exchange resin, which does the actual softening of water.

- A separate tank or compartment to store salt and for the makeup of the brine solution needed for regeneration.

- A master control valve that directs the flow of water through the regeneration cycle and service.

Softener Controllers

Today, just about all commercial and industrial (and even home water softeners) use what is technically known as the “sulfonated polystyrene copolymer cation exchange resin” product. Common salt (sodium chloride [NaCl] is considered the standard regenerant. Potassium chloride (KCl), however, can also be effective as an alternate at a little higher cost. This KCl regenerant can provide an almost sodium-free softened water supply.

The vast majority of commercial water softeners are engineered with self-monitoring control devices that determine when regeneration is necessary and automatically put the softener through the complete regeneration cycle. Fully automatic water softeners are divided into two classes: demand or timer-controlled.

Demand control devices are those that either:

- Meter the amount of water softened and trigger regeneration at a certain point;

- Measure (daily) the number of gallons of softened water used that day, calculate the reserve left in the tank, and automatically calculate the amount of salt needed for partial regeneration. This brings the entire system up to fully regenerated status for the following day’s use; or

- Have a sensor within the cation resin bed that signals when the softener is reaching the end of the softening run and automatically initiates regeneration of the system.

Electric or electronic time clocks that, at a set time every so many days, based upon a predetermined estimate of softened water usage, will automatically regenerate the softeners – whether needed or not.