Description

Membrane Clean-In-Place Systems

Engineered for on-site cleaning of Reverse Osmosis (RO) and other membrane based water treatment equipment. Periodic cleaning of the membrane elements will extend the useful life and greatly improve the economics of ownership. Systems are designed to work with all types of membrane cleaning procedures including inorganic mineral scale (low pH), biological/organic fouling (high pH), and sanitization cycles.

Each system includes a cleaning solution tank, transfer pump, and sediment filter to trap debris from re-entering the membranes during recirculation. All steps of the CIP process are to be performed manually by an equipment operator. The CIP system is available in two (2) types of design configurations:

Integral Mounted

The transfer pump is mounted, pre-piped, and pre-wired directly on the RO skid. Note that on 8” systems the RO filter housing is used as the CIP sediment filter. The cleaning solution tank is free-standing and can be stored when not in use. Includes a set of hoses and quick-connect fittings for the feed and return lines to and from the RO skid.

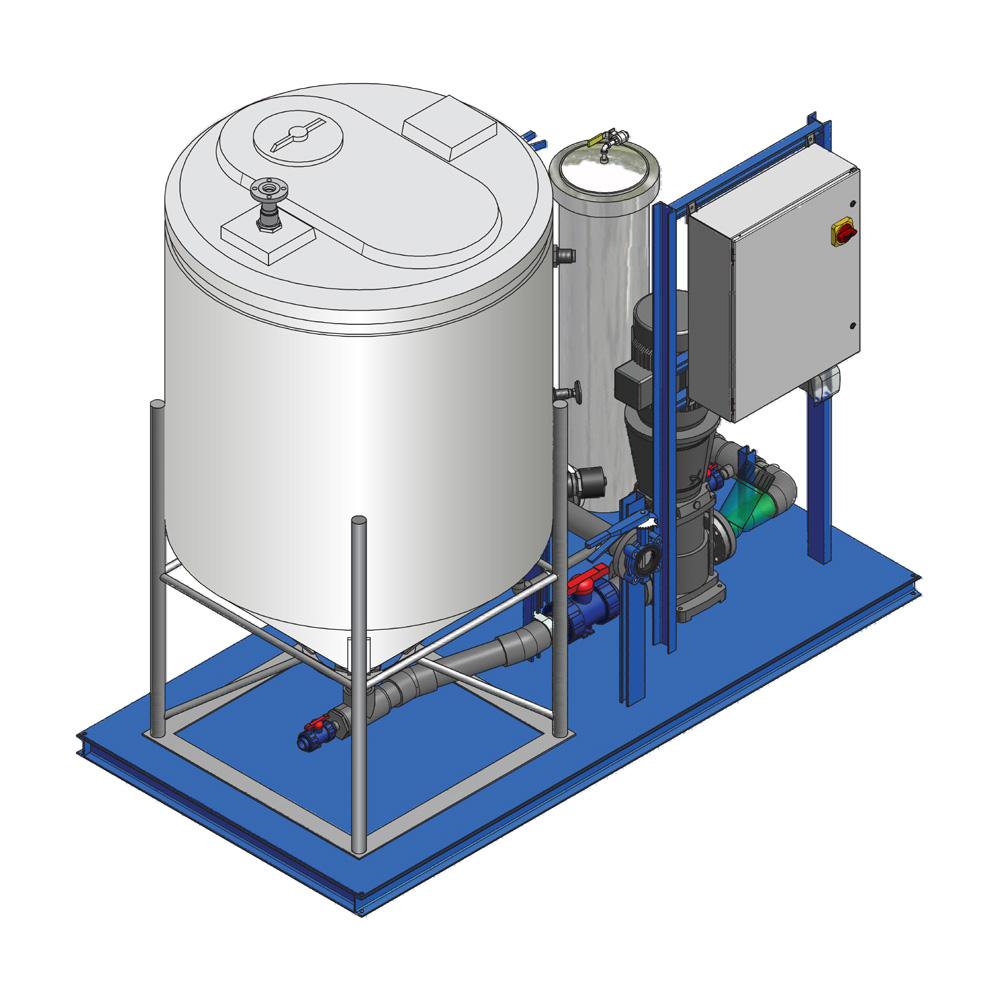

Skid Mounted

All CIP equipment including the cleaning solution tank are factory mounted, pre-piped, and pre-wired on a dedicated skid assembly. The Skid Mounted configuration is a good choice for installations where multiple RO systems are in place or where a hard piped CIP system is desired. This option can also be modified for portability for easy movement to storage or other locations within the plant.

Materials of Construction

• Skid Frame: Epoxy-coated carbon steel

• Solution Tank: Polyethylene

• Feed Pump: 304 Stainless Steel

• Prefilter Housing: Polypropylene or 304SS

• Interconnecting Piping: Sch 80 PVC

• Hardware & Fasteners: Stainless Steel

Standard Features

• Conical-Bottom, Closed Top Cleaning Solution Tank

• Centrifugal Transfer Pump with TEFC Motor

• Sediment Cartridge Filter Housing (25-micron rating)

• Pre-Wired Motor Starter with Fused Disconnect Switch

• NEMA-4 Electrical Enclosures

• Low Tank Level Switch with Automatic Pump

Shutdown

• Temperature Indicator

• Flow Indicator

• Pump Discharge Pressure Indicator

• Manual Recirculation Line for Solution Mixing

• Manual Tank Drain Valve

• Flexible Hose Assemblies with Quick-Disconnects

(Integral Mount)

Optional Equipment Available

• Variable Frequency Drives (VFD)

• pH Monitor

• Immersion Heater with Adjustable Thermostat

(Skid Mount Only, with Low Level Shutdown)

• UL-508A Rated Electrical Panels

• CPVC Piping

• All Stainless Steel Piping and/or Skid

• Portability for Skid Systems (Hose Kit & Caster Wheels)