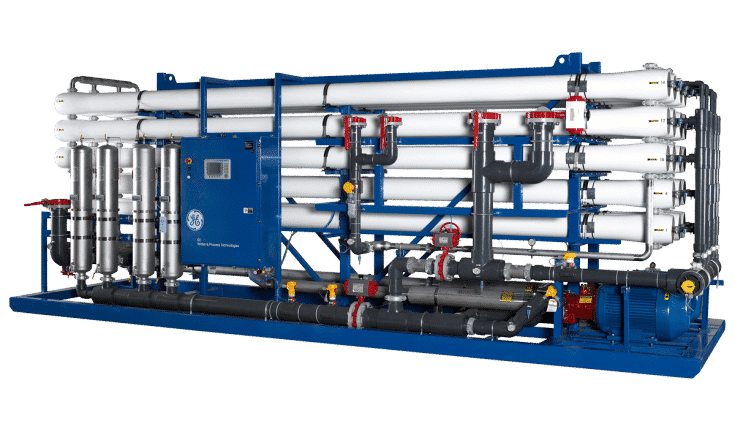

Osmonics Pro Series Reverse Osmosis Discontinued

It was announced this year that the OSMO Pro Series Reverse Osmosis Line will be discontinued. They have switched over to ProFlex which allows you some customization along with some pricing reduction. Complete Water Solutions will continue to support the OSMO Pro Series Reverse Osmosis Equipment. Complete Water Solutions provides parts, membranes, troubleshooting along with onsite service.

Need Osmonics Manuals? Click Here

Need A OSMO Pro Series Trouble Shooting Guide? Click Here

Need Service Or Parts Click Or Call (855) 787-4200

Some of the unique features of the OSMO Pro Series Reverse Osmosis

Specific Basic Features (BAS)

- GE Fanuc QuickPanel 6.0-inch monochrome display Touch screen controls

- GE Fanuc Versamax Micro Communication RS232

- 4-20 mA instruments displayed on instrument center

- UL/cUL Electrical Panel

Specific Premium Features (PRE)

- GE Fanuc Quickpanel, 12.0-inch color display Text and pictorial operating screens, Touch screen controls

- GE Fanuc Versamax, Communication: Ethernet

- 4-20 mA instruments on QuickPanel

- Primary and final pressure transmitters

- RO permeate flush on shutdown

- UL / cUL Electrical Panel

- pH Meter on RO Feed

Instrumentation

Flow Meters

- Permeate

- Concentrate

OSMO PRO-50-NA Reverse Osmosis

Conductivity

- Permeate

- Pressure

- Pre & Post Cartridge Filter

- RO Feed

- Pump Outlet

- Interstage (x2)

- Concentrate

- Permeate

Pressure Switch

- Feed, Permeate

- Concentrate

pH (Optional)

- Feed

ORP (Optional)

- Feed

Instrument Center (BAS)

- Signet 8900 Multimeter

Options Available

- Allen Bradley Compact Logix PLC Control Package

- Motor Starter

- Variable Frequency Drive

- ORP Meter

- pH Meter (Option for basic)

Membrane Options:

- 400 Square Foot Elements

SS8516 Tonkaflo Pump

- High Rejection Elements

PRO NA Accessories

- PRO Multi-Media filters

- PRO Activated Carbon and Softeners

- PRO Clean-in-Place units

- PRO Chemical Feed Systems

- Transfer Pumps and Storage Tanks

Operating Parameters

Design Recovery 1………………………………………………………………. 80%

Design Temperature ……………………………………………………………60oF (16oC)

Operating Temperature Range………………………………………………35-85oF (2-29oC)

Nominal rejection ……………………………………………………………….97-99%

System Inlet Pressure…………………………………………………………. 30-60 PSI

1 Recovery Rate can vary +/- 5%

Materials of Construction

High-pressure piping………………………………………………………….. 316 Stainless Steel, Sch. 10

Low-pressure piping …………………………………………………………. PVC, Sch. 80

Frame……………………………………………………………………………….Painted blue carbon steel

Enclosure………………………………………………………………………….Nema 4

Clamps/fittings…………………………………………………………………. Zinc-plated

Membrane Elements and Housings

Membrane Model ……………………………………………………………AG8040F

Style …………………………………………………………………………….. Spiral-wound elements

Manufacturer………………………………………………………………….GE

Membrane type ………………………………………………………………TFC (Polyamide)

Average membrane flux…………………………………………………… 16-17 gfd1

Membrane rejection ………………………………………………………..99.0 to 99.5%

Manufacturer…………………………………………………………………..GE

Housing material………………………………………………………………316 Stainless Steel or FRP

Housing Pressure Rating …………………………………………………..450 psi

Cartridge Filtration

Housing model……………………………………………………………….. HX-0740-80-V316

Housing material ……………………………………………………………. 316 Stainless Steel

Cartridge filter ………………………………………………………………..1-micron nominal, ROsave.Z*s

PRO 50 NA Reverse Osmosis

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com