100 GPM Reverse Osmosis System

Complete Water Solutions designed and provided a 100 GPM Reverse Osmosis System (Located Outside Of Charlotte N.C.). The system was sized based on the customer using an average of 60-80 GPM Average. This will reduce the duty cycle of the RO System. The RO Water is used for boiler feedwater, production, and sanitization. The RO water system was designed with the following equipment:

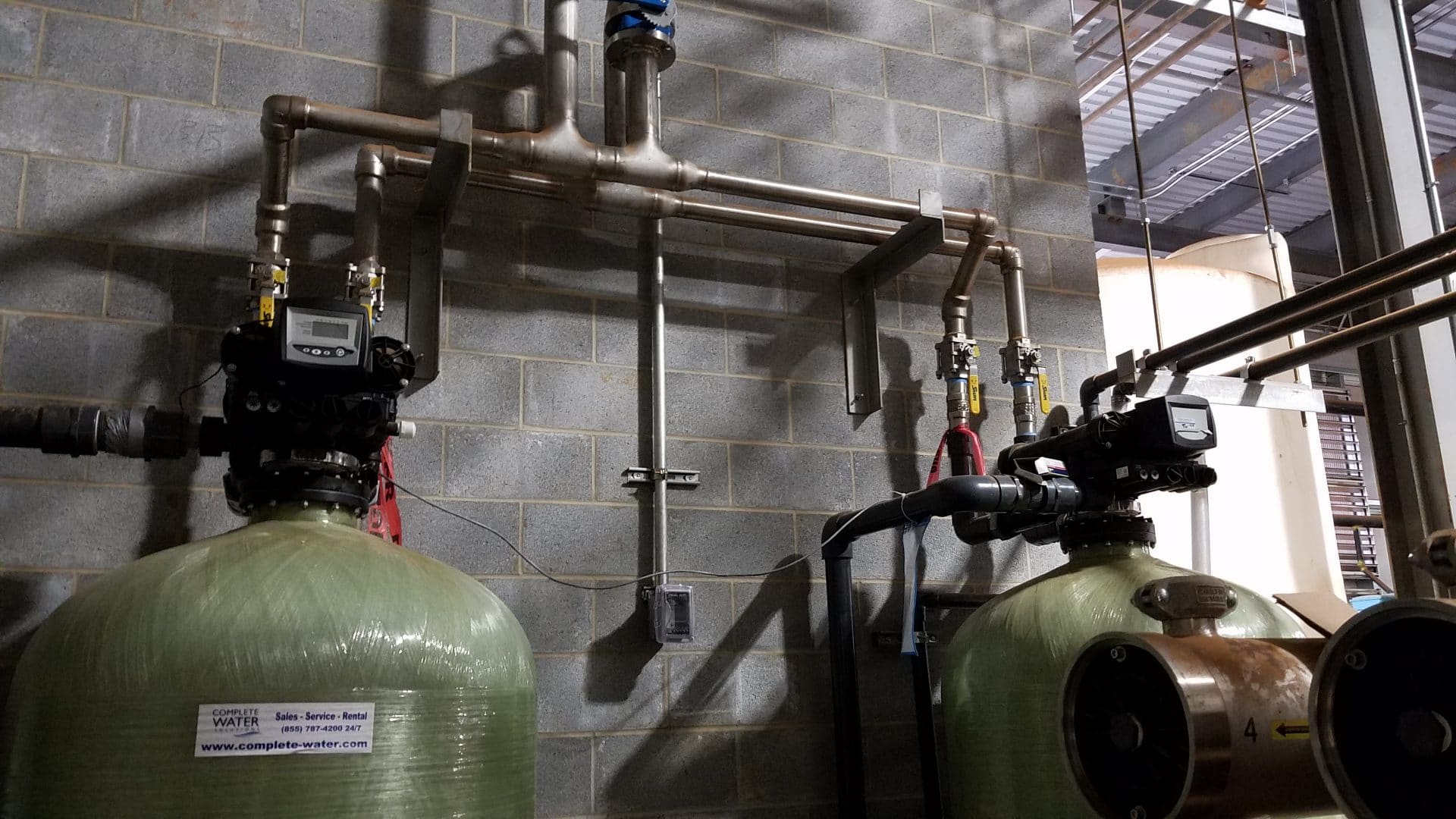

Carbon Filter

The carbon filter is put in place to remove chlorine before the RO System.

- C36-D Duplex Carbon Filter Carbon Filter Data Sheet

- Magnum Valve IT Filter Valve

- 764 Logix Controller

- Internal Meter

- Transformer

- 20 Cubic Feet Per Each Tank

Antiscalant

The antiscalant is used to control water hardness minerals from precipitating out in the RO System causing scale build-up on the RO Membranes. The Avista Vitec 5100 is an NSF Approved Product and was tested and verified to be a good choice with the incoming water feed. (Click Here To Learn More)

- Vitec 5100 w/Grundfos Pump

- Vitec 5100 Antiscalant

- Grundfos Chemical Pump DDA 7.5-16

RO System

The RO System selected for this job was the Osmonics E8-144K-DLX RO System complete with membranes that will allow the machine to produce 100 GPM @ 55 Degree F. The RO System is in place to reduce TDS. The reduction in TDS helps with boiler feed, sanitization, and production. The RO System came complete with the following:

- E8-144K-DLX E8 RO Sales Sheet

- Pressure Gauges

- High-Pressure Pump

- CIP System – Pump & CIP Tank

- Burkert 8620 Controller

- AK8040F-400 RO Membranes

- RO PX05-40XK RO Pre Filters

Polishing Softener

The polishing softener was provided to remove any remaining hardness post-RO before the boiler feed water tank. The softeners are a duplex twin alternating unit. The units came complete with the following:

- S30-A Twin Alternating Softener Softener System Data Sheet

- 15 Cubic Feet Per Tank Cation Sodium Softener Resin

- Magnum Controller

- 764 Softener Digital Controller

- Brine Tank Assembly

- Air Check Assembly

Supplied was a 3,600 Gallon Storage Tank with duplex RO Water distribution pumps. The storage tank was equipped with with a IFM Efector 4-20mA digital level controller which ties directly back into the RO System. The distributions pumps are stainless steel in construction. The pumps also came equipped with VFD to hold and maintain pressure.

Need An RO System – Contact Our RO Experts!

info@complete-water.com

(855) 787-4200

With over 30 years of hands-on experience in the water treatment industry, Nathan Olszak is a trusted water treatment expert. He specializes in designing, engineering, and servicing water treatment systems. As the owner of Complete Water Solutions, Osmonics, and Membrane Cleaning Pro, Nathan has built a reputation for delivering customized water treatment solutions that enhance efficiency, reliability, and water quality across various industries, including the medical, commercial, and manufacturing sectors.

Nathan’s journey in water treatment began as a service technician. He gained in-depth knowledge by working with all major brands of equipment, including Veolia, Suez, Bruner, Culligan, Pentair, Aquamatic, Osmonics, GE Water, Marlo, Lakeside, Fleck, Autotrol, US Filter, ION Pure, Siemens, Evoqua, and many others. This hands-on expertise, combined with his technical certifications, has made him a leader in water system engineering and water management.

Credentials & Expertise

- Certifications: David H. Paul Reverse Osmosis Certification, PLC Programming

- License: Power Plant Operating Engineer 3rd Class

- Specialties:

- Design & engineering of water treatment systems and advanced water systems

- Custom water filtration systems and solutions

- Installation, automation, and repair of water treatment systems

- Expertise in Reverse Osmosis (RO), Deionization, Water Softening, Carbon Filtration, Iron Filtration, UV Treatment, Ultrafiltration (UF), Process Filtration, CEDI/EDI, and more

- Specialized knowledge in Boiler Feed Water, Tower Makeup Water, and drinking water production for industries such as bottling, pharmaceuticals, and food processing

- Project management and reclaiming of water system waste for other uses

- Evaluation of raw water sources and potential contamination risks

- Industrial water treatment strategies to prevent corrosion and optimize system performance

- Boiler water treatment to enhance energy efficiency and system longevity

Nathan’s commitment to excellence extends beyond equipment sales and service. He works closely with clients to develop tailored water treatment services that optimize performance and meet their operations’ unique demands. His expertise covers methods that mitigate water impurities, ensure fresh water accessibility, and maintain regulatory compliance. It also includes the design of high-efficiency reverse osmosis systems for industrial use.

Nathan focuses on the latest technology in water conditioning, water softeners, filters, and pumps to improve maintenance and efficiency. His experience in laboratory testing and biofilm control ensures the highest industry standards in water treatment processes and water management.

Additionally, his deep understanding of infrastructure and water data analysis provides long-term, cost-effective solutions that promote health and safety. His expertise ensures that businesses receive top-tier, quality water treatment solutions.

For insights into the latest industry trends, innovations, and best practices, explore the Complete Water Solutions Blog, where Nathan shares valuable information on water filtration systems, sustainability, and water solutions engineering.

Give Us A Call (855) 787-4200 or Email info@complete-water.com