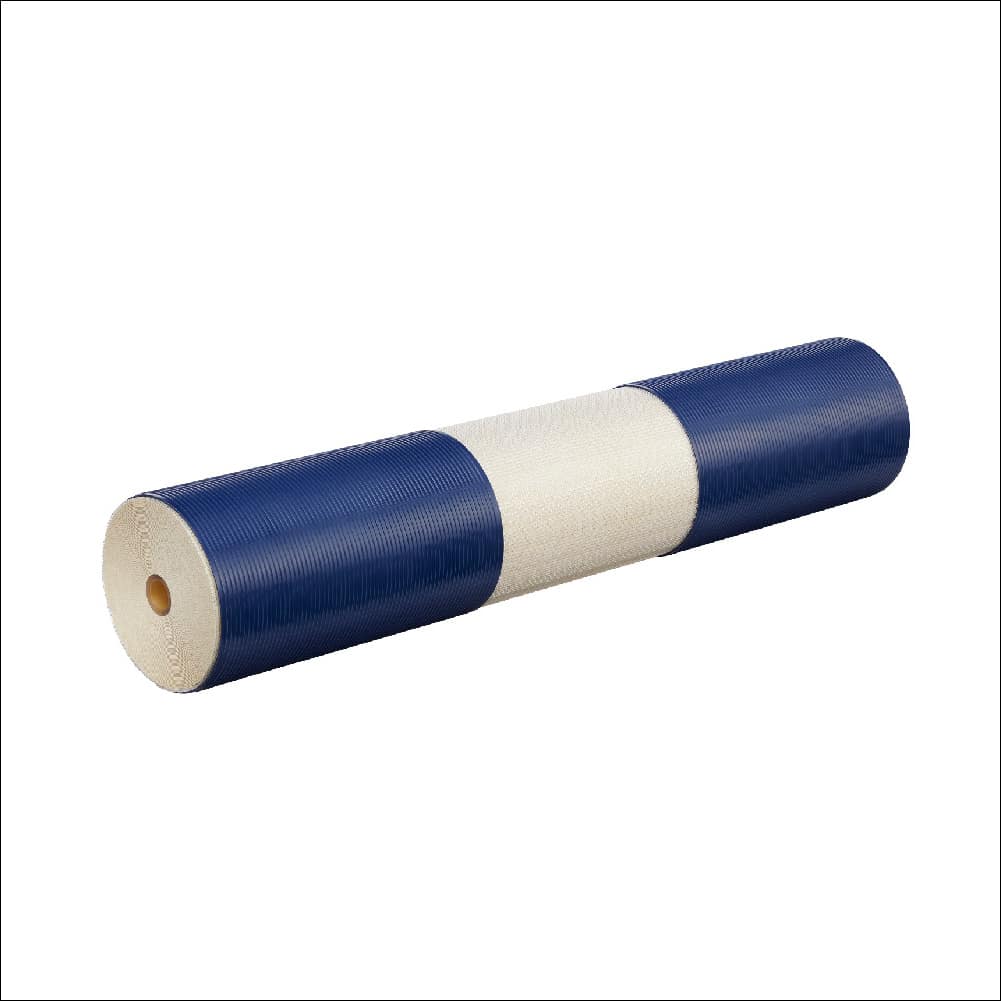

Optum Series Elements are used for critical food and dairy separation processes where high production yields and state-of-the-art sanitary construction is required. This series includes Optum Reverse Osmosis (RO) and Optum Nanofiltration (NF) elements. The Optum Series elements feature the next level of performance including:

• Reduced energy consumption and carbon footprint of the recirculation pump by up to 9% versus other shelled elements and up to 25% versus standard cage-wrapped elements. The Optum Series elements have an innovative design that creates shelled ends by the use of two engineered sleeves that minimize fluid bypass; thereby reducing recirculation pump requirements

• Improved employee ergonomics with 10-20% less force required during installation and removal. Optum Series elements also maintain better element scroll integrity during operation than standard cagewrapped elements leading to easier removal and improved operational lifetime

• Blister-free construction from previous generations of products, in our sanitary portfolio, is utilized in the Optum Series elements, along with a Durasan* cage underneath the sleeves

• Reduced plastic waste versus other shelled elements. In a plant with 200 elements, using Optum Series elements for 10 years will keep over 1,100 lbs (500 kg) of plastic out of landfills

• High performance reverse osmosis membrane used in the Optum RO elements maximizes concentration and dewatering with high rejection of dissolved solids and low molecular weight organic constituents such as lactose and those that create BOD/COD (biological oxygen demand/chemical oxygen demand)

• Differentiated nanofiltration membrane, as used in Dairy D-Series elements and the Optum NF elements, is characterized by a molecular weight cutoff of 150-300 Dalton for uncharged organic molecules and its ability to preferentially reject divalent and multivalent ions while passing monovalent ions as needed for lactose and whey desalting

• Extended shelf life is provided through enhanced packaging techniques

• Strict product compliance is a foundation of our sanitary portfolio including use of materials compliant with US FDA 21 CFR (Subchapter B, Parts 175, 176, 177, 178, and 182) and EU regulations (1935/2004 and 10/2011). Optum elements also have kosher and halal certification.

Typical Operating Pressure: 200 – 500 psi (1,379-3,447 kPa)

Typical Operating Flux: 5 – 20 GFD (8-34 LMH)

Clean Water Flux (CWF): 14 GFD (24 LMH) @ 225 psi

Maximum Operating Pressure: 800 psi (5,516 kPa)

Maximum Permeate Pressure: 60 psi (413 kPa)

Maximum Temperature: 122°F (50°C)

pH Range: 2.0 – 11.0

Maximum Pressure Drop:

Over an element: 15 psi (103kPa)

Per housing: 60 psi (414 kPa)

Chlorine Tolerance: 1,000 ppm-hours dechlorination recommended